High Recovery Rate Lead And Zinc Ore Flotation Plant Froth Flotation Cell

Leadzinc flotation: A review on nearly six decades of

2024年9月15日 The objective is to present detailed and referable information for the flotation of lead–zinc sulfide ores, thus giving valuable guidance in reagent system innovation and 2022年5月12日 flotation experiments were carried out on a plant sample of the lead flotation feed and highintensity conditioning (HIC) was used to improve flotation recovery The results Improving the lead flotation recovery at Lakan leadzinc 2024年6月1日 Constrained by factors such as low sulfidation rates and the propensity for sulfidation products to desorb, flotation recovery of lead–zinc oxide ores remains low At Efficient flotation separation of lead–zinc oxide ores using 2021年2月4日 After lead flotation at optimum pH 8, the flotation of zinc at a different pH (5–115), with two collector types, was performed to study the recovery and grade of zinc in Critical importance of pH and collector type on the flotation

.jpg)

A Process Mineralogy Approach to the Flotation of Complex Lead–Zinc

2022年3月22日 As seen from Table 4, lead flotation results improved slightly as a concentrate of 624% Pb was obtained with 4055% recovery However, unlike to lead flotation, the grade and 2023年9月2日 Flotation experiments were conducted in a flotation cell (model XFD III, Jiangxi Weiming Machinery Equipment Co, Ltd, Jiangxi, China) To create a pulp density of ~28%, 400 g of leadzinc oxide ore and a specific Process Mineralogy Characteristics and Flotation 2022年4月1日 A sampling campaign carried out on the lead flotation circuit at Lakan leadzinc processing plant demonstrated that the Pb recovery was only about 6869% Characterization (PDF) Improving the lead flotation recovery at Lakan leadzinc 2022年8月12日 In the rougher flotation stage, a lead concentrate with 1729% Pb and a zinc concentrate with 989% Zn could be obtained by 7671% lead and 1549% zinc recoveries A Process Mineralogy Approach to the Flotation of

Efficient flotation recovery of lead and zinc from refractory leadzinc

2021年5月1日 In this study, a new flotation approach, a lowalkaline and nondesliming process, was introduced for improving lead and zinc recoveries, lowering production cost and reducing 2016年4月27日 The classifier overflows a product at approximately 80 mesh directly to the flotation machine where a cleaned and recleaned lead concentrate is combined with the concentrate of the 4 cell lead flotation machine Zinc How to Process LowGrade Lead Zinc Ore by 2024年10月19日 Separation Preferential flotation, zinc suppression and lead recovery Collector: lowgrade xanthate, highgrade xanthate and black drug It is usually separated in alkaline medium Inhibitors: CN , NaCN, KCN, ZnSO4, Customized Leadzinc Ore Flotation Plant2023年9月2日 The beneficiation of lowgrade oxidized lead and zinc ore from the Lanping mine has attracted extensive interest in the mineral processing field due to the extremely rich resource reserves and the challenge in lead and zinc Process Mineralogy Characteristics and Flotation

A New Innovative Method of Flotation Separation for High Sulfur Lead

2020年1月25日 Galena–Pyrite Bulk Flotation The particle size has a significant effect on the flotation behaviors of minerals; therefore, the effect of grinding fineness (−0074 mm) on galena pyrite bulk flotation was firstly investigated and the results are shown in Fig 2a As can be noted that the recovery of lead , zinc , and sulfur was increased simultaneously as the proportion of 2023年9月2日 lectors was proposed as an efficient reagent regime to beneficiate zinc and lead from the ore Moreover, an allopen flotation process was employed to avoid the undesirable effects of slimes The aim of this paper is to develop an effici ent flotation process to selectively separate zinc and lead from highoxidized lead zinc oreProcess Mineralogy Characteristics and Flotation 2022年4月1日 A sampling campaign carried out on the lead flotation circuit at Lakan leadzinc processing plant demonstrated that the Pb recovery was only about 6869%(PDF) Improving the lead flotation recovery at Lakan leadzinc 2014年10月1日 The tailing in a large leadzincironsulfur multimetallic mine has rich reservation in variety of metallic minerals It has been difficult to recover because of all kinds of reasons The challenges faced by leadzinc ore beneficiation are, low grade and recovery of lead and zinc concentrate for fine disseminated grain size, high oxidation rate and close intergrowth This Study on Recovery of LeadZinc Tailing Ore by Electrochemical Flotation

1 Froth Flotation – Fundamental Principles

2009年8月27日 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry The particles with attached air bubbles are then carried to the surface and2022年5月11日 increased recovery of fines and smaller plant footprint Metso Outotec Concorde Cell™ – Recover the unachievable ore value Set a new benchmark in high intensity pneumatic flotation by recovering unachievable fine and ultrafine particles This results in significant revenue gains as well as minimizes plant operating costs, energy andFlotation technologies Metso Outotec keeping costs 2021年11月1日 Froth flotation is a physicochemical separation technique that exploits the difference in the surface wettability of mineral particles (Wills and Finch, 2016)From a heterogeneous mixture of solids, hydrophobic particles are made to attach to gas bubbles and subsequently carried to the froth phase and recovered as a froth product (typically the value Hydrodynamics of froth flotation and its effects on fine and 2022年4月1日 Froth flotation was undoubtedly the most innovative and groundbreaking discovery for mining in the 19th century (Wills and Finch, 2015)Nevertheless, it did not last long that scientists recognized its limitations for extremely fine and coarse particles, which has remained a longstanding unsolved issue in the mineral processing field (Gaudin et al, 1931)Technological assessments on recent developments in fine

.jpg)

Highturbulence fine particle flotation cell optimization and

2024年10月4日 Considering the characteristics of microfine ore particles, such as small size, low specific gravity, large specific surface area, and similar surface physicochemical properties, researchers have 2021年11月1日 In a mechanical flotation cell, macro hydrodynamics is responsible for solids suspension and aggregates transport, and microturbulence plays an important role in the subprocesses of flotation (PDF) Hydrodynamics of froth flotation and its effects on fine 2018年10月1日 Simulated wastewaters (concentrate and tailings thickener overflows), from a future leadzinc flotation separation plant, were treated for the removal of target metal ions (Zn 2+, Pb 2+ and Cu 2+) and suspended solids (01–05 g L −1)The ions were adsorbed onto ferric hydroxide precipitates, and then removed by dissolved air flotation (DAF)Treatment and water reuse of leadzinc sulphide ore mill wastewaters Introduction Froth stability plays an important role in determining selectivity and recovery in flotation (Farrokhpay, 2011) It should be noted that froth with very high stability is not desirable because in addition to recovering the particles attached to the bubbles, it creates favourable conditions for entrainment (Zheng, Franzidis, and Johnson, 2006)Effects of flotation operational parameters on froth stability

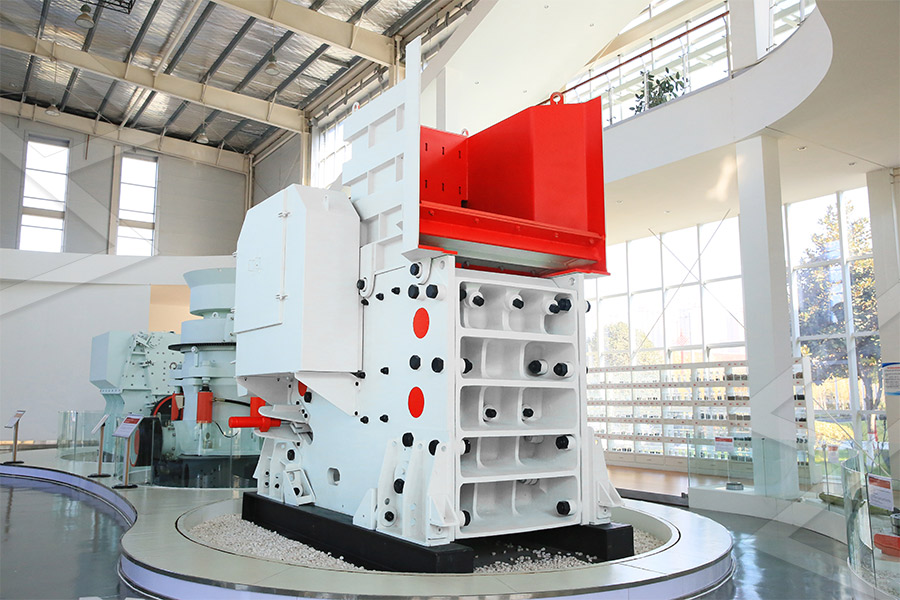

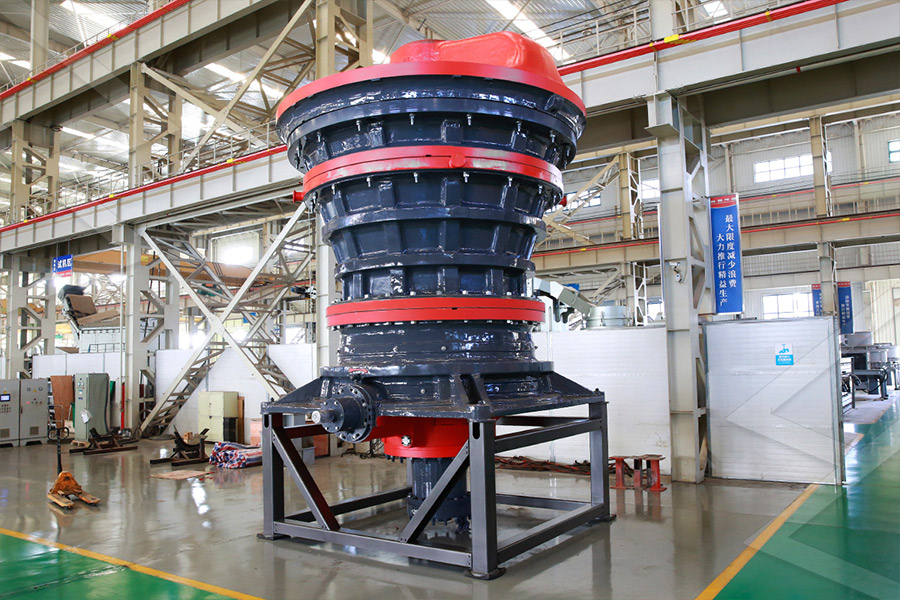

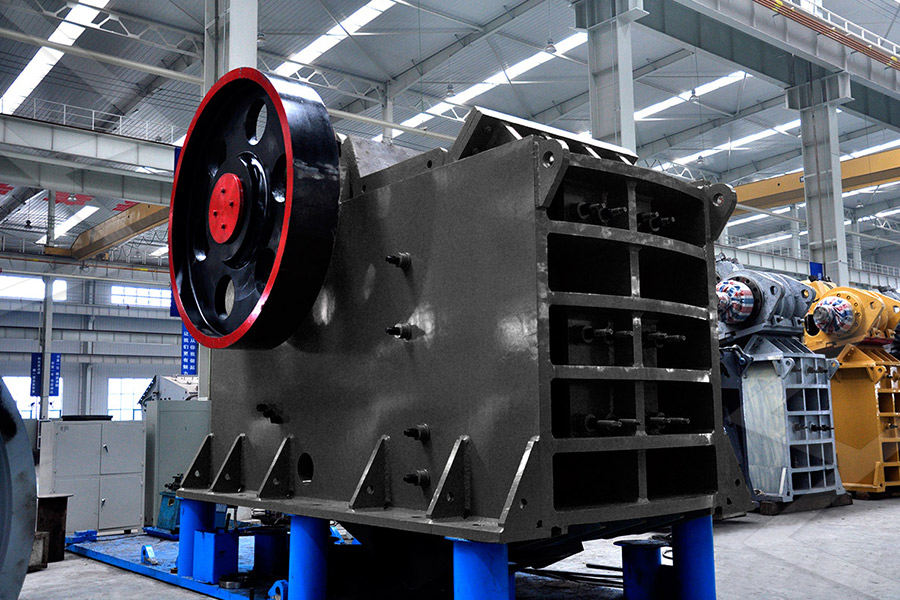

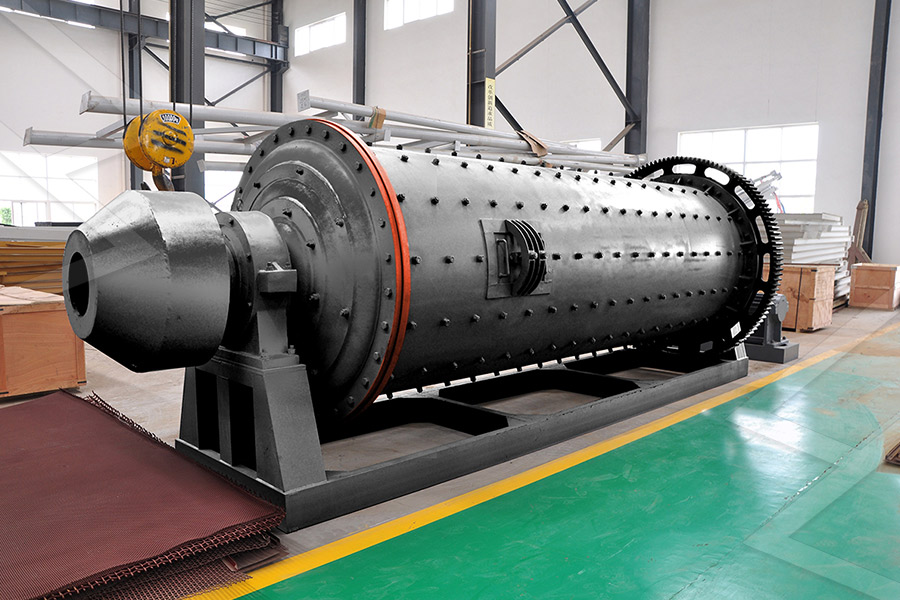

Flotation Machine for Lead and Zinc Ore Flotation

2024年10月18日 Flotation Machine for Lead and Zinc Ore Flotation Beneficiation Mineral Processing Plant Flowchart US$1,00000100,00000 / set 1 set (MOQ)2011年9月14日 Recirculating material through a flotation plant results in decreased residence time of material per flotation cell, but does allow for the valuable material to spend more time in the flotation plant as a whole; and, subsequently, increases the A review of froth flotation control ScienceDirect2023年11月1日 The focus of this study was to investigate the effects of salinity on the recovery of lead and zinc sulfide via flotation Future studies will incorporate these findings and further examine the effects of salinity on the flotation of a complex Pb/Zn sulfide ore, in the presence of some common flotation reagentsThe effects of saline water on the recovery of lead and zinc 2007年12月31日 Most of the lead–zinc ore contains silver and to a lesser degree, gold Almost 85% of the silver production in the world comes from lead–zinc oresFlotation of LeadZinc Ores ResearchGate

.jpg)

Volatilization behavior of lead, zinc and sulfur from flotation

2024年1月15日 High S content in the flotation products may reduce zinc recovery and a large amount of S entering the gas phase will lead to a high concentration of SO 2 in the flue gas, increasing the cost of flue gas treatment Under the air atmosphere and high temperature conditions, the carbon in the briquettes will occur incomplete combustion to form CO 2021年6月24日 Flotation data for the design of process plants Part 2 – case studies R C Dunne*1, G S Lane2, G D Richmond3 and J Dioses2 The Cadia Hill Gold Mine and the Hellyer copper, zinc and lead plant present different problems with widely different target grind sizes, liberation characteristics The contrast is between Hellyer sFlotation data for the design of process plants Part 22020年1月1日 The hydrometallurgical route of zinc hydroxide and synthesis of nanocrystalline ZnO is a particularly attractive method to recover oxidized lead and zinc from leadzinc flotation tailings In (PDF) Recovery of ZnO from leadzinc flotation 2014年8月4日 The use of recycled water in flotation has significant effects on flotation and selectivity because the recycled water contains many dissolved compounds and ions that alter the chemistry of the Effect of Water Composition on Flotation of Lead and Zinc Sulphide Ore

.jpg)

A significant review of froth stability in mineral flotation

2024年9月19日 Flotation was first performed in 1860 (Arbiter, 2000) and is a technology that utilizes the differences in physicochemical properties of various mineral surfaces to achieve specific separation (Wills and Munn, 2005), as depicted in Fig 1This process involves hydrophobic particles adhering to air bubbles being transported to the froth layer, whereas 2020年8月31日 Entrainment is a process by which fine and ultrafine particles are transferred to the flotation froth from the top of the flotation pulp, and eventually discharge to the concentrate product, even when they are not attached to gas bubbles Therefore, entrainment can be considered as a twostep process, one at the upper layer of the pulp to the flotation froth, and Entrainment of Gangue Minerals in Froth Flotation Springer2011年1月1日 After froth flotation, each product of froth flotation recovered (froth and depressed) were allowed to settle for 24 hours before decanting, filtered, dried at a temperature of 105 °C and weighed(PDF) Fundamental principles of froth flotation ResearchGate2019年6月24日 There are abundant lowgrade zinc oxide ores in Yunnan Province, China, but it is extremely difficult to recover Zn and Pb from them using traditional technology They are often stockpiled during the exploitation of sulfide ores and highgrade zinc oxide ores and become a kind of solid waste In this study, a novel methodology using surface modification by sulfidation Flotation of a LowGrade Zinc Oxide Ore After Surface

Galena Sphalerite Flotation Separation Method

2016年4月23日 The problem of treating oxidized leadzinc ores for the production of highgrade lead zinc flotation concentrates is a complex problem due to the nature of the ores and to the soft sliming characteristics of the lead and zinc minerals The ore for treatment is a leadzinc carbonate ore in a mixed siliceouslime carbonate gangue The association of the minerals 2016年4月27日 The classifier overflows a product at approximately 80 mesh directly to the flotation machine where a cleaned and recleaned lead concentrate is combined with the concentrate of the 4 cell lead flotation machine Zinc How to Process LowGrade Lead Zinc Ore by 2024年10月19日 Separation Preferential flotation, zinc suppression and lead recovery Collector: lowgrade xanthate, highgrade xanthate and black drug It is usually separated in alkaline medium Inhibitors: CN , NaCN, KCN, ZnSO4, Customized Leadzinc Ore Flotation Plant2023年9月2日 The beneficiation of lowgrade oxidized lead and zinc ore from the Lanping mine has attracted extensive interest in the mineral processing field due to the extremely rich resource reserves and the challenge in lead and zinc Process Mineralogy Characteristics and Flotation

A New Innovative Method of Flotation Separation for High Sulfur Lead

2020年1月25日 Galena–Pyrite Bulk Flotation The particle size has a significant effect on the flotation behaviors of minerals; therefore, the effect of grinding fineness (−0074 mm) on galena pyrite bulk flotation was firstly investigated and the results are shown in Fig 2a As can be noted that the recovery of lead , zinc , and sulfur was increased simultaneously as the proportion of 2023年9月2日 lectors was proposed as an efficient reagent regime to beneficiate zinc and lead from the ore Moreover, an allopen flotation process was employed to avoid the undesirable effects of slimes The aim of this paper is to develop an effici ent flotation process to selectively separate zinc and lead from highoxidized lead zinc oreProcess Mineralogy Characteristics and Flotation 2022年4月1日 A sampling campaign carried out on the lead flotation circuit at Lakan leadzinc processing plant demonstrated that the Pb recovery was only about 6869%(PDF) Improving the lead flotation recovery at Lakan leadzinc 2014年10月1日 The tailing in a large leadzincironsulfur multimetallic mine has rich reservation in variety of metallic minerals It has been difficult to recover because of all kinds of reasons The challenges faced by leadzinc ore beneficiation are, low grade and recovery of lead and zinc concentrate for fine disseminated grain size, high oxidation rate and close intergrowth This Study on Recovery of LeadZinc Tailing Ore by Electrochemical Flotation

1 Froth Flotation – Fundamental Principles

2009年8月27日 1 Froth Flotation – Fundamental Principles Froth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry The particles with attached air bubbles are then carried to the surface and2022年5月11日 increased recovery of fines and smaller plant footprint Metso Outotec Concorde Cell™ – Recover the unachievable ore value Set a new benchmark in high intensity pneumatic flotation by recovering unachievable fine and ultrafine particles This results in significant revenue gains as well as minimizes plant operating costs, energy andFlotation technologies Metso Outotec keeping costs