Concrete Mining Mill 10104 Dimensions

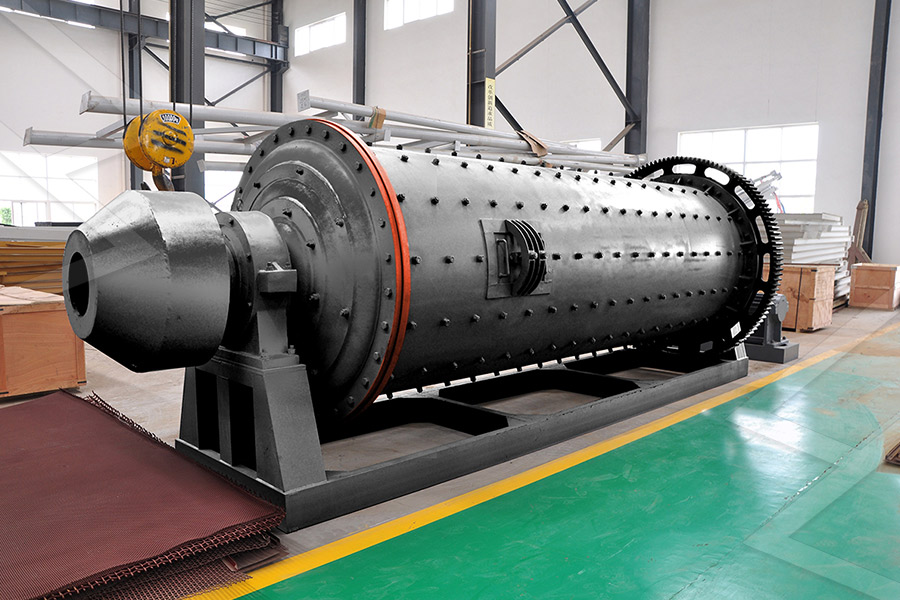

BALL MILLS Ball mill optimisation Holzinger Consulting

2021年3月12日 Ball mill optimisation As grinding accounts for a sizeable share in a cement plant’s power consumption, optimisation of grinding equipment such as ball mills can provide significant cost and CO2023年4月23日 A comparison of the grinding media is given together with the knowledge gaps that still need to be bridged to improve the quality and performance of grinding media used in (PDF) Grinding Media in Ball MillsA Review ResearchGate2021年1月1日 A twocompartment ball mill with a highly efficient separator is still procured for new cement grinding units installation, although the vertical roller mill has now become a true Review on vertical roller mill in cement industry its Your operation requires a Semi Autogenous Mill (SAG mill) or Autogenous Mill (AG Mill) that is flexible, durable, costefficient and tailored to your specific needs and use cases That's why we offer a full product range from 43m to 122m in SAG Mill Autogenous and SemiAutogenous

CEMTEC Mining Technology

CEMTEC tube mills are available in a wide variety of designs, sizes and power capacities Each machine is tailormade according to the requirements of individual customers CEMTEC’s product range also includes a number of 2006年1月1日 PDF Dramatic shortcomings of mill liner designs, especially of large semiautogenous grinding (SAG) millssuch as rapid failure, mill shell damage Find, read and cite all the research(PDF) Selection and design of mill liners2011年2月1日 In this study, in order to evaluate and compare the performances of different cement grinding technologies using the ball milling and high compression technology, Comparison of the overall circuit performance in the cement 2024年10月15日 Our technical team and sales experts can help you identify the best solution for your mineral grinding applications through a complete service system including mineralogical analysis, grinding mill selection, process Grinding Mills Mineral Processing Equipment

A review of modeling and control strategies for cone crushers

2021年8月15日 Minetomill optimization strategies in which blasting, crushing, grinding, and flotation processes are considered simultaneously to determine the best overall settings to China Cement Ball Mills wholesale Select 2024 high quality Cement Ball Mills products in best price from certified Chinese Ball Machine manufacturers, Cement Plant suppliers, wholesalers China Cement Ball Mills, Cement Ball Mills Wholesale, 2024年3月22日 Airswept coal mills produced by AGICO CEMENT have 13 models according to their cylinder sizes THE THREE ADVANTAGES OF AGICO BRAND Rich Production Experience AGICO CEMENT Ball Mill for Sale Cement Mining and Chemical 2020年5月21日 Irregular concrete surface is unsafe for wheel tires Due to this irregularity the noise caused due to friction increases too Milling helps in restoring the smooth concrete surface This results in better road experience Concrete Milling: Why, What and How to Mill

Concrete Blocks: Dimensions, Sizes and Types

2024年5月8日 Discover the different types of concrete blocks used in construction, including hollow, solid, and aerated concrete blocks Learn about their dimensions, prices, and applications for loadbearing walls, insulation, The cement ball mill can perform dry process production and also wet process production, moreover it can do grinding and drying at the same time CHAENG cement ball mill has features of small investment, high rate of return, simple process and easy operation Advantages of CHAENG cement ball mill: 1Cement ball mill Xinxiang Great Wall Machinery Co, LtdRedesigned specifically for cement and mining, our MAAG® GEAR LGDX Lateral Gear Unit adapts to different installation sites on the circumference of your mill The installation flexibility of the LGDX, coupled with our clever approach to lubrication and easy maintenance, make it the perfect fit for your grinding processesCement MAAG Gear2023年10月10日 While not as widely used as some other types of grinding equipment in copper ore mining, rod mills offer distinct advantages in certain applications due to their efficient operation and ability to produce a specific range of particle sizes Tower Mill The Tower Mill is another type of grinding mill used in the mining industry This vertical Understanding the SAG Mill in Copper Ore Mining Process

Choose the Best Grinding Steel Balls for Your Ball Mill Fote

4 天之前 1 When you use the ball mill for the first time In the first time, the grinding steel balls must be added at 80% of the maximum ball loading capacity of the ball mill And three sizes of balls, namely, large, medium and small, are required for proportioning Different ball mill models have different ball loading capacitiesThis review serves to highlight problems of mill liner designs and how they can be tackled in a logical and often inexpensive manner by considering charge trajectories and liner spacing criteria, in conjunction with liner wear monitoring Dramatic shortcomings of mill liner designs, especially of large SAG mills, such as rapid failure and even mill shell damage arising from impacting of the The selection and design of mill liners Semantic Scholar2024年4月30日 However, when integrating mining tailings into 3D concrete mixtures, it is important to consider certain factors that may affect the behaviour of the concrete 31 General Aspects Tailings present the opportunity to be utilized as fine aggregate or supplementary material in concrete mixtures due to their propertiesTailings as a Sustainable Resource in 3D Printed Concrete for 2023年8月23日 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement To achieve this crucial transformation, a cement mill comprises What Are the Parts of a Cement Mills?

Processing of laboratory concrete demolition waste using ball mill

2023年3月21日 Using CD waste in construction can reduce both the demand on natural aggregates and the disposal of CD waste in landfills Since the early 1970 s, the scientific community has been interested in the utilisation of CD waste, such as recycled aggregate [16]The feasibility and potential applications of recycled concrete aggregate have been 2024年10月13日 Grinding mills operate on the principle of breaking down ore particles into smaller sizes through the action of abrasion The primary types of grinding mills include ball mills, rod mills, autogenous mills, and semiautogenous mills Each mill type has a distinct working mechanism, but they all share common principles of crushing and grindingUnderstanding the operation of grinding mills in the mining Бисер 10104 Tropic Seas Mill Hill купить с доставкой по всему миру, оптом и в розницу Цена: 178 грн ТелефонViberWhatsApp: +380930308330 • Бисер 10104 Tropic Seas Mill Hill ⋆ DimensionsTitle: Mill Hill Glass Magnifica Beads; By: Mill Hill / Wichelt Imports; Size: 225 mm (14/0) Cylindrical Cut beads, 2 gram package; This is a new and unused, factory sealed package of Tropic Seas colored Mill Hill Magnifica Beads (Mill Hill #10104) The beads are blue / green color These small, cylindrical cut beads are 225 mm (14/0) in Mill Hill Magnifica Glass Beads 2g Tropic Seas #10104

Infrastructure and Construction Materials Guide — Cement

5 天之前 It is mixed with sand and larger aggregate sizes, formed into “concrete” when hardened (setup), and then provides a final structure Typical concrete compressive strength (ability to resist applied force) ranges from 2000 psi (pounds per cubic inches) to 6,000 psi depending on the mix of cement and aggregate typesEasily find the perfect fit from our wide range of sizes We provide SAG and AG Mills up to 122m in diameter Our mills use conventional geared drives for transmitting up to 18,000 kW of power by use of a twin pinion system FLSmidth is a full flowsheet technology and service supplier to the global mining and cement industries We help our SAG Mill Autogenous and SemiAutogenous Mills FLSmidth2024年2月16日 The content provides a comprehensive overview of mining mills, including their types, key components, operation, applications Skip to content 22 Oct 2024 Mining and Material Handling Losses: Mitigation Strategies and Efficiency Improvement; CuttingEdge Mineral Comminution Innovations;Advancements in Mining Mill Technology: Efficiency, China Mining Roller Mill wholesale Select 2024 high quality Mining Roller Mill products in best price from certified Chinese Mining Machine manufacturers, Mining Machinery suppliers, wholesalers and factory on MadeinChina Mining Machine Concrete Powder Mill Grinding Mill Limestone Raymond Mill 4r Roller Mill US$ 86668888 / Piece China Mining Roller Mill, Mining Roller Mill Wholesale,

.jpg)

AusIMM – Leading the way for people in resources

%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 Increase the energy efficiency of your vertical roller mill Reducing energy consumption is a top priority for both environmental and economic reasons But you can't afford to lose performance in your VRM Our MAAG® GEAR CEM Drive system achieves both, powering VRMs up to 14 000 kW with a compact integrated motor that reduces power loss by more than 20%MAAG® GEAR CEM Drive2023年4月23日 2 Department of Mining Engineering, mill dimensions, and breakage kinetics parameters of cement clinkers was higher with cylpebs grinding media than with steel balls in a ball mill(PDF) Grinding Media in Ball MillsA Review ResearchGate3 天之前 Contractors often adhere to National Concrete Masonry Association guidelines to determine masonry dimensions for various projects, such as certain styles of stone walls For example, project managers can use 31 pieces of 25 Mastering Concrete Block Dimensions To Find

China Ball Mill Cement, Ball Mill Cement Wholesale,

China Ball Mill Cement wholesale Select 2024 high quality Ball Mill Cement products in best price from certified Chinese Grinding Equipment manufacturers, Cement Plant suppliers, wholesalers and factory on MadeinChina Ball Mill with Large Diameter Sizes US$ 20000 / Piece 1 Piece (MOQ) CITICIC Luoyang Heavy Machinery Co, Ltd The mill used for this comparison is a 44meter diameter by 136 meter long ball mill with a 5000 HP drive motor It is designed for approximately 90 ston per hour This type twocompartment mill is a state oftheart shell supported cement finish mill The torque and time requirements of the mill with the ballBALL MILL DRIVE MOTOR CHOICES Artec Machine2024年2月23日 The operation of the cement raw mill is a critical step in cement production By grinding the raw materials into a fine powder, these powders can be more easily mixed with other cement ingredients and burn more evenly during the cement clinker process Therefore, the efficient operation of the cement raw mill directly impacts the production efficiency and quality How Does a Raw Mill Work in a Cement IndustryAirswept coal mills produced by AGICO CEMENT have 13 models according to their cylinder sizes The diameter and length are between Φ1200×2400Φ2900×4700 (mm), and the matching motor power is 45570KW, which can meet 14 16 t/h pulverized coal production Widely used in the preparation of coal powder in electric power, metallurgy Air Swept Coal Mill Cement Plant Equipment Coal Grinding Mill

.jpg)

Concrete Milling 101 What is the concrete milling process?

Concrete milling is the process of removing the top layers of a concrete surface It’s carried out using scarifying machines equipped with diamondtipped blades Milling operations are effective at creating level, smooth surfaces that provide a lot of traction Plus, the material that’s chipped away can be repurposed for aggregate material Hammermill Crushers are known to generate material finer than 3/16" (4mm), which in some applications may be undesirable However, if there is a market for finer material, or if it is acceptable within the desired product size, Hammermills can achieve reduction ratios that may otherwise require multiple crushersHammermill Crushers McLanahan2024年3月22日 Airswept coal mills produced by AGICO CEMENT have 13 models according to their cylinder sizes THE THREE ADVANTAGES OF AGICO BRAND Rich Production Experience AGICO CEMENT Ball Mill for Sale Cement Mining and Chemical 2020年5月21日 Irregular concrete surface is unsafe for wheel tires Due to this irregularity the noise caused due to friction increases too Milling helps in restoring the smooth concrete surface This results in better road experience Concrete Milling: Why, What and How to Mill

.jpg)

Concrete Blocks: Dimensions, Sizes and Types

2024年5月8日 Discover the different types of concrete blocks used in construction, including hollow, solid, and aerated concrete blocks Learn about their dimensions, prices, and applications for loadbearing walls, insulation, The cement ball mill can perform dry process production and also wet process production, moreover it can do grinding and drying at the same time CHAENG cement ball mill has features of small investment, high rate of return, simple process and easy operation Advantages of CHAENG cement ball mill: 1Cement ball mill Xinxiang Great Wall Machinery Co, LtdRedesigned specifically for cement and mining, our MAAG® GEAR LGDX Lateral Gear Unit adapts to different installation sites on the circumference of your mill The installation flexibility of the LGDX, coupled with our clever approach to lubrication and easy maintenance, make it the perfect fit for your grinding processesCement MAAG Gear2023年10月10日 While not as widely used as some other types of grinding equipment in copper ore mining, rod mills offer distinct advantages in certain applications due to their efficient operation and ability to produce a specific range of particle sizes Tower Mill The Tower Mill is another type of grinding mill used in the mining industry This vertical Understanding the SAG Mill in Copper Ore Mining Process

.jpg)

Choose the Best Grinding Steel Balls for Your Ball Mill Fote

4 天之前 1 When you use the ball mill for the first time In the first time, the grinding steel balls must be added at 80% of the maximum ball loading capacity of the ball mill And three sizes of balls, namely, large, medium and small, are required for proportioning Different ball mill models have different ball loading capacitiesThis review serves to highlight problems of mill liner designs and how they can be tackled in a logical and often inexpensive manner by considering charge trajectories and liner spacing criteria, in conjunction with liner wear monitoring Dramatic shortcomings of mill liner designs, especially of large SAG mills, such as rapid failure and even mill shell damage arising from impacting of the The selection and design of mill liners Semantic Scholar2024年4月30日 However, when integrating mining tailings into 3D concrete mixtures, it is important to consider certain factors that may affect the behaviour of the concrete 31 General Aspects Tailings present the opportunity to be utilized as fine aggregate or supplementary material in concrete mixtures due to their propertiesTailings as a Sustainable Resource in 3D Printed Concrete for 2023年8月23日 A cement mill is a fundamental component of the cement manufacturing process, playing a vital role in breaking down and grinding cement clinker into fine powder This finely ground powder, when mixed with other materials, produces the building material we commonly know as cement To achieve this crucial transformation, a cement mill comprises What Are the Parts of a Cement Mills?