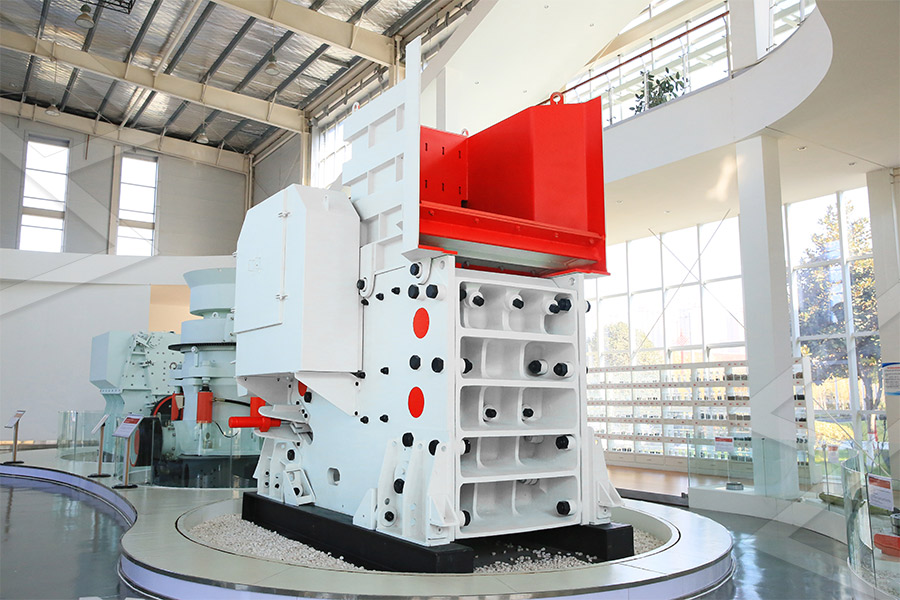

Songling Main Product Double Roll Rock Crusher

New insights into double roll crushing ScienceDirect

2023年11月1日 Double roll crushing is a comminution principle that has already been deployed for more than 100 years It is known for high throughputs of sometimes sticky materials such 2023年9月7日 FLS Double Roll Crushers are capable of impressively high throughput rates – up to 14,000 tph – thanks to the customised tooth and liner design and optimised installed Product datasheet Double R oll Crusher DRC 1818 The FLSmidth Double Roll Crusher DRC withstands the toughest mining conditions while delivering consistent, highperformance crushing thanks to its working principle and several key features In the DRC the feed material is fed Double Roll Crusher DRC FLSmidthFLS Double Roll Crushers are capable of impressively high throughput rates – up to 14,000 tph – thanks to the customised tooth and liner design and optimised installed power and drive set Roll crushers – ERC and double roll crusher – FLS

.jpg)

Design, Fabrication and Testing of a Double Roll Crusher

2024年7月25日 A double roll crusher consists of two rolls Crushing takes place between two cylindrical rolls with each rotating about a concentric horizontal shaft in opposite directions 2017年4月1日 Double roll crushers (DRC) have the highest throughputs among primary crushers In the oil sands, the hourly capacity may exceed 14,000 t/h They are preferably Dynamics in double roll crushers ScienceDirectDoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie clay, marl, limestone and similar raw materials Sticky and soft materials are reliably crushed in 2 or 3 stages down to the DoubleRollCrusher thyssenkrupp Polysius2023年8月9日 The paper presents results of extensive investigations exploring the influences of compressive strength, roll peripheral speed, feed particle size distribution, and single large New insights into double roll crushing,Minerals Engineering

2PG SERIES DOUBLE ROLLER CRUSHER

2022年2月22日 Double roll crushers are used for both, primary and secondary crushing They guarantee a strictly defined final grain size with a minimum of fine grains Raw materials, 2022年7月7日 Double Roller Crushers are Roller Crushers that are widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, and Double Roller Crushers SolidsWiki2024年4月19日 There are two main types of roller crushers: singleroll crushers and doubleroll crushers Singleroll crushers are equipped with a rotating cylinder which squeezes the material against a fixed plate or screen The doubleroll Types of Crushers Explained: Everything You 2023年11月1日 The core of the test plant is a double roll crusher DRC 450x450 toothed rolls Fig 3 shows a 3D view of the crusher without the drive units and inlet hopper The roll crusher has two cylindrical rolls, which are designed as fixed (2) and retractable (4) The retractable roll is pretensioned with two hydraulic cylinders (3), which press it New insights into double roll crushing ScienceDirect

}@~3SRDG`IA1KP_ICWAA.jpg)

Double Roll Crusher Product Information

KURIMOTO, LTD Product Information, Double Roll Crusher Userfriendly, highfunctional Crusher Supports a wide variety of crushed particle sizes Designed to bite objects between the two rolls and crush the objects using a builtin hybrid Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feedsDouble Roll Crushers McLanahan2024年7月15日 VSI crusher is generally used for the third or fourth stage crushing after the first and second crushers, which is the final link of aggregate production It is the best machine to produce manufactured sand even better than a roll crusher The final product of the VSI crusher is cubic in wonderful shape even can replace natural sandWhat Are the Differences Between The 7 Types of Crushers?DOUBLE ROLL CRUSHER DR13 Features Solution for mediumhard rock as well as sticky and soft materials (coal, limestone, clay, salt, etc) Weldon hardfaced crushing teeth with various configurations for most difficult applications Integrated flywheel equalizing torque peaks, thus reducing required motor power Permanent parallel position of crushing rolls due to hydraulic Double Roll Crusher CPC GmbH Crushing Processing

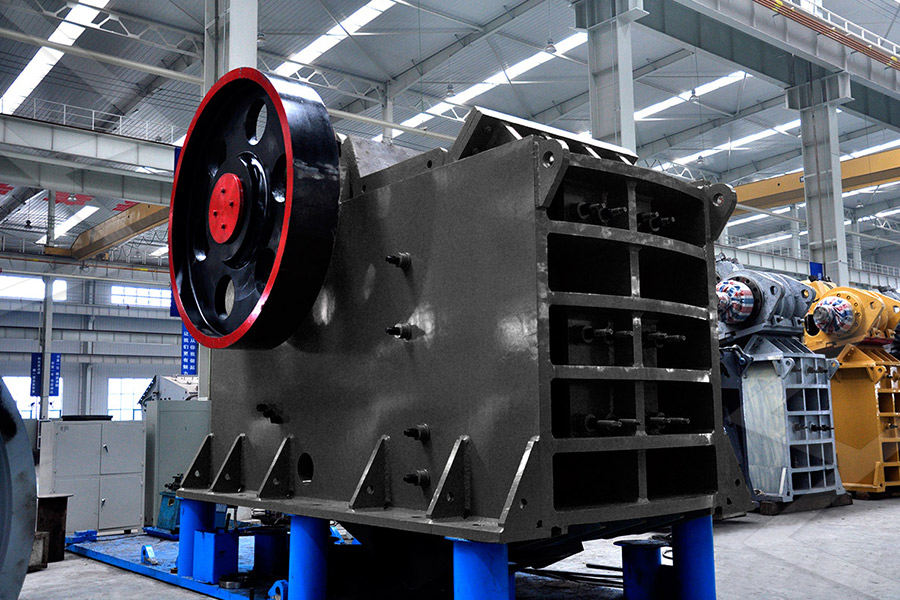

Design, Fabrication and Testing of a Double Roll Crusher

2024年7月25日 Figure 1: Double roll crusher geometry 215 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5] For rolls that have equal radii and length, tangents drawn at the point of contact of the particleOur Eccentric Roll Crusher ERC® offers an innovative and patented design that enhances performance and durability We have mounted the roll eccentrically between the crushing chamber and the integrated screening chamber to increase wear resistance, improve efficiency and achieve optimized, betterintegrated and automated mining crushing operationsEccentric Roll Crusher ERC® FLSmidth2 天之前 Used as a primary or secondary unit, double roll crushers can be used in nearly any application with even the hardest, most abrasive material This efficient crusher can lower power requirements for producing material and, with its unique features, can increase machine lifeDouble Roll Crushers Astec5 天之前 Binder+Co Double roll crusher An optimum grain size of 10 to 50 mm is crucial for sensorbased sorting of cullet since a higher content of fines (010 mm) would have an unfavourable effect on sorting performance In the form of the double roll crusher, Binder+Co has created the ideal prerequisite for the subsequent sorting of waste glassDouble Roll Crusher Binder+Co

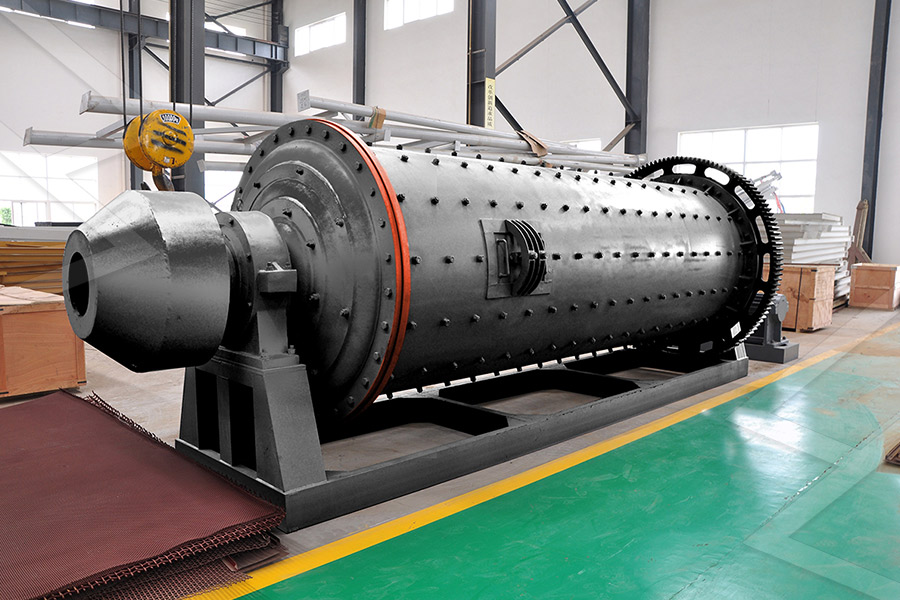

rock crusher,stone crusher,double roll

Huashengming Heavy Machinery Factory Crusher, Stone Crushing Equipment, aggregate processing equipment, Roll Crusher Sieving Equipment for sand, quarry, mining and construction Manufacturer from Gongyi City, Henan Quality Manufactory Price Rock Stone Double Roller Roll Crusher find quality Sand Production Line Machines, Crusher Sand Production Line Machines from Shanghai Lipu Heavy Industry Co, Ltd of China Suppliers China Manufacturer with main products:Mining Machinery Crushers ,Ball Mills ,Rotary Dryers ,Magnetic Separators Manufactory Price Rock Stone Double Roller Roll Crusher2008年4月9日 The doubleroll crusher model, first proposed by Austin et al [15] and lately refined by Austin et al [16], is based on the following assumptions: a) breakage of each size particle occurs independently of the other sizes, b) provided the roll diameter is large enough compared with the feed size and gap, the product size distribution depends Modeling of an industrial doubleroll crusher of a urea The rolls crushers we sell are used in mining and parallel industries; a double rolls crusher is a common type of equipment used as a primary crusher for sizing ore Roll crushers are used for sizing sintered coals, soft and medium hard rocks, fertilizers and saltsThe crushing material is fed on the top of the whole width of the rolls with the help of feeders10″ TO 12″ DOUBLE ROLL CRUSHERS 911Metallurgist

.jpg)

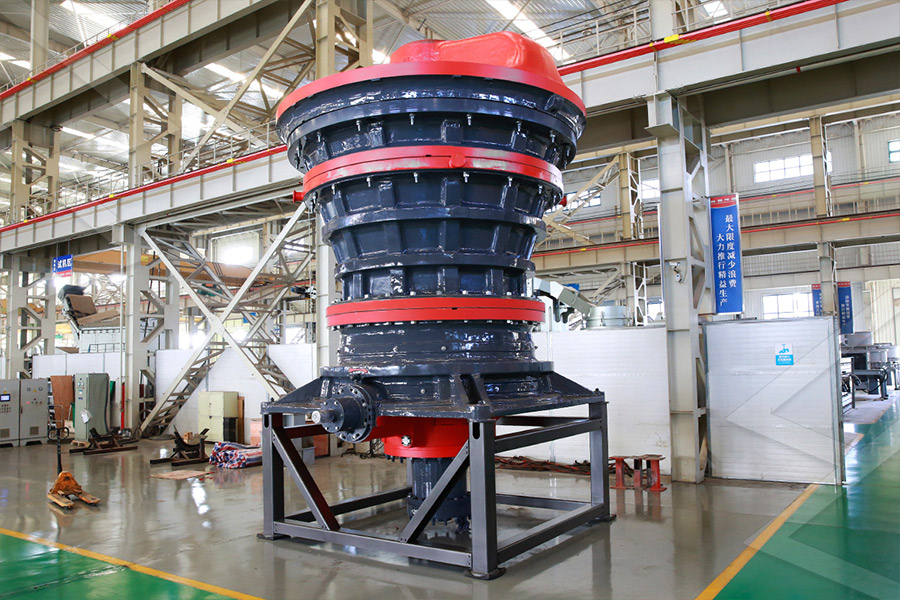

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 During operation, the highspeed rotating impeller scatters and crushes the material, which then collides and grinds together before discharge There are two crushing methods: rockonrock and rockoniron Roll Crusher Roll crushers crush materials through the compression action of two rotating rollers They are commonly used as tertiary Roll Crusher Introduction Roll Crusher is mainly applied in mine, cement, metallurgy, chemical, electric power, coal and other industries, especially for crushing various materials with medium hardness And it has the features of simple structure and convenient operation and maintenance Main Technical ParametersDouble Roll Crusher PTVALTEKINDO GLOBAL INTERTEK2017年4月1日 They are preferably used to comminute mediumhard rock or sticky materials An unusual tough particle or unbreakable object may effect substantial dynamic forces in a DRC (DRC) and jaw crusher product with crushing gap indication As a result, the forces acting in a double roll crusher could be much higher, at least locally, as one Dynamics in double roll crushers ScienceDirect2024年6月28日 Rock crushers, specially designed machines, play a vital role in industries like mining, construction, and recyclingThey are responsible for breaking down large rocks into smaller, more manageable pieces for different applications There are two main groups of rock crushers: compressive crushers, which include primary crushers used in the first stage of the Crusher Rock: Exploring the Types of Rock Crushers

Modeling of coal breakage in a doubleroll crusher

2012年12月1日 Austin et al [12] proposed a mathematical description of a size–mass balance model for the breakage process in a doubleroll crusher The model has been investigated in a number of studies [13], [14], [15], [16]The equation for calculating the product size distribution of the product of the roll crushing of a given feed was formulated in terms of two basic China Small Double Roll Crusher wholesale Select 2024 high quality Small Double Roll Crusher products in best price from certified Chinese Small Drilling Machine manufacturers, Double Stainless Steel suppliers, wholesalers and factory on MadeinChina Small Quartz Limestone Rock Stone Sand Making Roll Crusher Price, Coal Double Small Double Roll Crusher MadeinChinaChina Double Roll Crushers wholesale Select 2024 high quality Double Roll Crushers products in best price from certified Chinese Double Plus manufacturers, Double Machine suppliers, wholesalers and factory on MadeinChina Top Quality High Pressure Double Roll Crusher for Coal/Rock/ Minerals US$ 490019000 / Piece 1 Piece (MOQ)China Double Roll Crushers, Double Roll Crushers Wholesale 2024年10月13日 In addition, the finished product provided by its crusher has a uniform particle size, which can ensure the accuracy and reliability of experiments and analysis When using a lab roll crusher, it is necessary to adjust the rollers’ spacing and rotation speed according to the sample’s nature and the required degree of crushing to obtain the Lab DoubleRoll Crusher JXSC Mining

polysius® crusher thyssenkrupp Polysius Crushing

DoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie clay, marl, limestone and similar raw materials Sticky and soft materials are reliably crushed in 2 or 3 stages down to the required product sizeDoubleRollCrushers are used for the crushing or mediumhard rock as well as for sticky and soft materials, ie clay, marl, limestone and similar raw materials Due to the low crushing ration, the thyssenkrupp Polysius DoubleRollCrusher is producing a product size ditribution with less content of fines and therefore it is the most DoubleRollCrusher thyssenkrupp Polysiusdouble roll crusher manufacturers/supplier, China double roll crusher manufacturer factory list, find best price in Chinese double roll crusher manufacturers, suppliers, factories, exporters wholesalers quickly on MadeinChina Main Products: Mining Machine , Rock Crusher, Iron Remover , Feeder Machine , Screening Machine RD Double Roll Crusher Manufacturers Suppliers3 天之前 DOVE Roll Crusher also referred to as Double Roller Crusher, or Twin Roll Crusher is highly efficient crushing machine, used in certain applications for primary, secondary and tertiary crushing applications DOVE Roller crushers are highly practical crushers for soft to mediumhard ore and where the final crushed out put is required to be of uniform grain sizes, with minimum Roll Crusher Double Roller Crusher DOVE DOVE

2pgc Double Toothed Roll Crusher for Cement, Coal (2PGC900X900)

2024年8月27日 2pgc Double Toothed Roll Crusher for Cement, Coal (2PGC900X900), Find Details and Price about Crusher Double Toothed Roll Crusher from 2pgc Double Toothed Roll Crusher for Cement, Coal (2PGC900X900) ATAIRAC ENGINEERED PRODUCTS INC(CHINA) Product Introduction ATAIRAC PGQ Series roll crusher is applied to crush various medium All Products Overview; DRC Double Roll Crusher; SZR Sizer; SGC Sand and Grit Crusher; CRC Classic Roll Crusher; Double roll crusher with nonadjustable rolls for predefined applications ACR Double roll crusher with traditional Vbelt drive for low and medium rock hardness SGC Sand and Grit Crusher Based on DRC for the Innovative roll crusher technology Size Technology GmbH 2024年4月19日 There are two main types of roller crushers: singleroll crushers and doubleroll crushers Singleroll crushers are equipped with a rotating cylinder which squeezes the material against a fixed plate or screen The doubleroll Types of Crushers Explained: Everything You 2023年11月1日 The core of the test plant is a double roll crusher DRC 450x450 toothed rolls Fig 3 shows a 3D view of the crusher without the drive units and inlet hopper The roll crusher has two cylindrical rolls, which are designed as fixed (2) and retractable (4) The retractable roll is pretensioned with two hydraulic cylinders (3), which press it New insights into double roll crushing ScienceDirect

Double Roll Crusher Product Information

KURIMOTO, LTD Product Information, Double Roll Crusher Userfriendly, highfunctional Crusher Supports a wide variety of crushed particle sizes Designed to bite objects between the two rolls and crush the objects using a builtin hybrid Double Roll Crushers typically follow a primary or secondary crusher and are used for secondary and tertiary reduction of various minerals, such as ROM coal, clean coal, limestone, gypsum, trona, shale, bauxite, oil shale, coke, salt, lime, glass, kaolin, brick, shale and wet, sticky feedsDouble Roll Crushers McLanahan2024年7月15日 VSI crusher is generally used for the third or fourth stage crushing after the first and second crushers, which is the final link of aggregate production It is the best machine to produce manufactured sand even better than a roll crusher The final product of the VSI crusher is cubic in wonderful shape even can replace natural sandWhat Are the Differences Between The 7 Types of Crushers?DOUBLE ROLL CRUSHER DR13 Features Solution for mediumhard rock as well as sticky and soft materials (coal, limestone, clay, salt, etc) Weldon hardfaced crushing teeth with various configurations for most difficult applications Integrated flywheel equalizing torque peaks, thus reducing required motor power Permanent parallel position of crushing rolls due to hydraulic Double Roll Crusher CPC GmbH Crushing Processing

Design, Fabrication and Testing of a Double Roll Crusher

2024年7月25日 Figure 1: Double roll crusher geometry 215 Thickness of the RollFigure 1 is the geometry of a double roll crusher with a spherical particle about to enter the crushing zone of a roll crusher and is about to be nipped [4], [5] For rolls that have equal radii and length, tangents drawn at the point of contact of the particleOur Eccentric Roll Crusher ERC® offers an innovative and patented design that enhances performance and durability We have mounted the roll eccentrically between the crushing chamber and the integrated screening chamber to increase wear resistance, improve efficiency and achieve optimized, betterintegrated and automated mining crushing operationsEccentric Roll Crusher ERC® FLSmidth2 天之前 Used as a primary or secondary unit, double roll crushers can be used in nearly any application with even the hardest, most abrasive material This efficient crusher can lower power requirements for producing material and, with its unique features, can increase machine lifeDouble Roll Crushers Astec5 天之前 Binder+Co Double roll crusher An optimum grain size of 10 to 50 mm is crucial for sensorbased sorting of cullet since a higher content of fines (010 mm) would have an unfavourable effect on sorting performance In the form of the double roll crusher, Binder+Co has created the ideal prerequisite for the subsequent sorting of waste glassDouble Roll Crusher Binder+Co