Impact Crush Www Impact Crushers

.jpg)

IMPACT CRUSHERS HAZEMAG

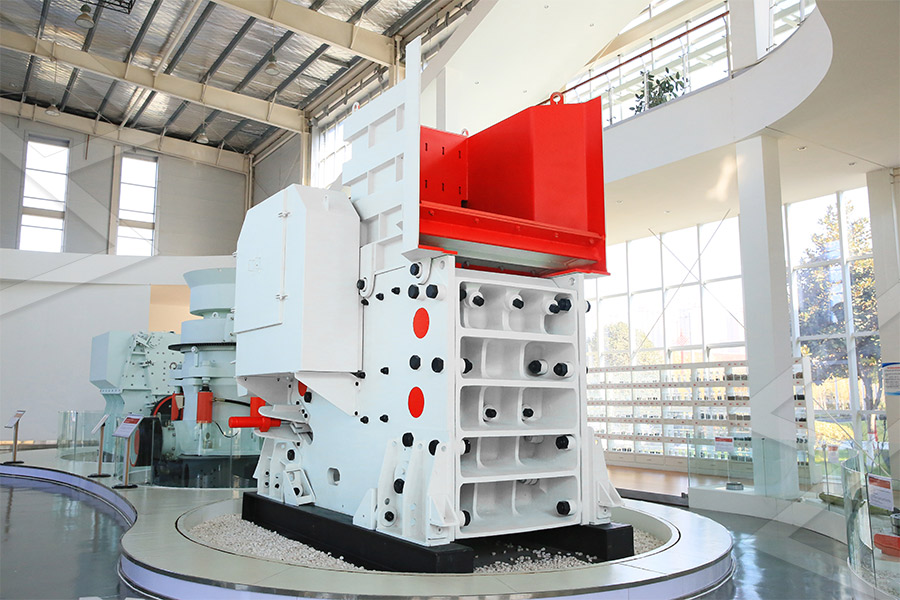

HAZEMAG impact crushers can handle individual lumps of feed material up to 8 tons in weight and 3 m3 (100 cuft) in volume, effecting the comminution process in a single pass at Impact crushers are named after the method they use in reducing larger blocks of rocks to smaller grain sizes As the name suggests, an impact crusher accelerates the feed material to high Impact crushers highquality impactors MetsoImpact crushers (eg, hammer mills and impact mills) employ sharp blows applied at high speed to freefalling rocks where comminution is by impact rather than compression The moving Impact Crusher an overview ScienceDirect Topics2024年3月1日 To faithfully encapsulate the dynamics of the impact swing in question, the study employs a plethora of assumptions, conditions, and reductions, elucidated comprehensively in Impact crusher kinematics: The dynamics of an impact swing

.jpg)

Impact Crusher Machines Williams Patent

Impact crushers rely on gravitational or dynamic physical impact for size reduction of materials such as rock, concrete, gravel, and more, rather than through a standard compressiononly method of crushingMobile impact crushers Sandvik Prisec™ impactor revolutionizes performance and versatility in mobile impact crushing Available in open or closed circuit, tracked or wheeled, the mobile impact crusher range offers unparalleled levels Mobile Impact Crushers, QI Mobile Impact 2024年10月15日 The Finlay® I140 tracked impact crusher shapes the future through innovation This new generation impact crusher with redefined style and advanced technological design gives improved material flow and production I140 Impact Crusher Horizontal Impactorthyssenkrupps new tertiary impact crusher for the production of gravel, chippings and sand from medium to hard rock The variopactor ® guarantees consistent product quality, high cubicity as well as high reliability and short maintenance variopactor® impact crusher manufactor

.jpg)

How Impact Crushers Work: A Comprehensive

2023年3月11日 Learn how impact crushers use highspeed impact force to break down materials and produce a uniform product size distribution Discover the benefits and limitations of this crushing machine and find the right MVIG Series vertical shaft impact crusher are designed to be used in tertiary or quarternary stage crushing These crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well Vertical Shaft Impact Crushers – G Model– MEKAWhat is an Impact Crusher? An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher Impact Crushers Stedman Machine CompanyThe beauty of impact crushers is their versatility in terms of input material and output size There are many different designs out there but generally speaking impact crushers can produce material from 3" down The smaller the input How does an Impact Crusher work? RUBBLE

Types of Crushers: Choosing the Right One for Each Stage

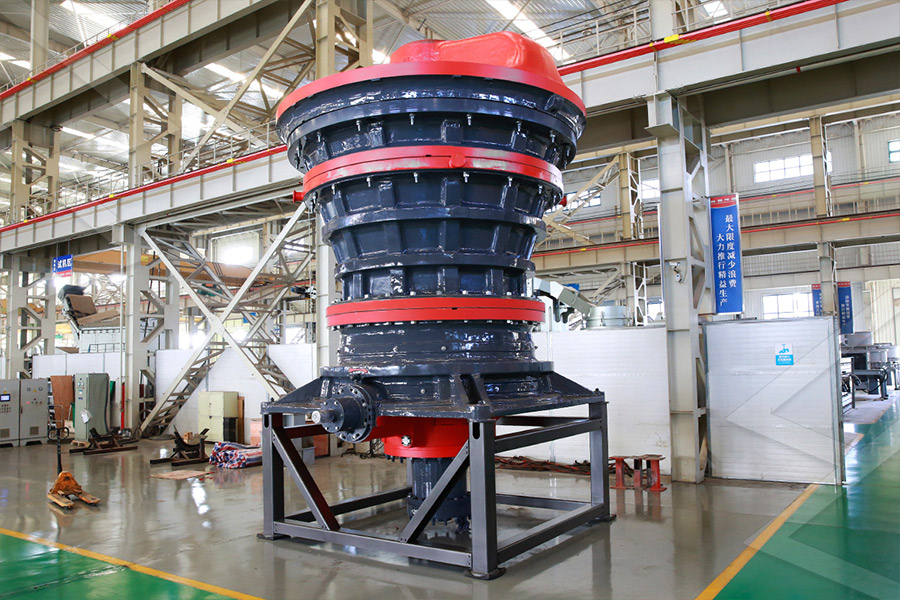

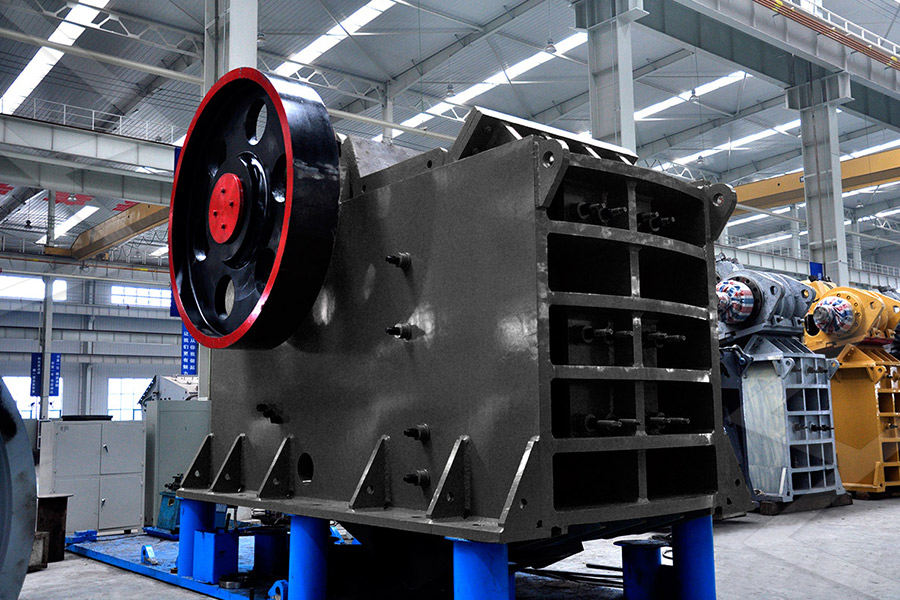

2024年7月17日 Choose gyratory or cone crushers for largescale production lines, and jaw or impact crushers for medium to smallscale operations 5 Investment and operating costs Initial investment: Gyratory and cone crushers have higher initial costs but lower longterm operating costs Jaw crushers and impact crushers are more costeffective initially2024年8月14日 The Industries Impact Crushers Serve Aggregate Productions Impact crushers are commonly used in the production of aggregate materials for construction projects They can effectively crush various types of rocks to produce aggregates of different sizes and shapes Mining Operations Impact crushers are used to reduce the size of ore particles Impact Rock Crushers: A Comprehensive Overview2024年10月18日 Impact Crushers are available in stationary, track, and portable configurations meeting any demand for any of these industries Although Impact Crushers generally have a higher operating cost than other crushers, they tend to produce a more uniform particle shape (cubical) which is desirable and produce more fines for hot asphalt producersWhat is an Impact Crusher? Zenith Crusher2024年4月19日 Secondary crushers crush materials in the size range of 50 mm to 300 mm, which is determined by the type and size of the crusher They produce output sizes from 6mm to 100mm Secondary crushers can be divided into three main types: cone crushers, roller crushers, and impact crushersTypes of Crushers Explained: Everything You Need to Know

Nordberg® NP Series™ impact crushers Metso

Nordberg® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs Nordberg® NP™ crushers have a unique blow bar attachment systemCrushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 65 Impact Crushers Impact crushers (eg, hammer mills and impact mills) employ sharp blows applied at high speed to freefalling rocks where comminution is by impact rather than compression The moving parts are “beaters,” which transfer some of Impact Crusher an overview ScienceDirect Topics2023年2月23日 What is an Impact Crusher? Impact crushers, also known as impactors or horizontal shaft impact crushers, are crushing machines that use the principle of impact crushing to crush materialsThey are commonly used in mining, construction, and recycling industries to produce highquality cubical aggregates from various materials, including hard rock, soft rock, Understanding the Impact Crusher Working Principle for2024年3月4日 Mining Operations:In mining applications, impact crushers are employed to crush hard and abrasive materials such as ore and minerals Their robust construction and high capacity make them suitable for primary and secondary crushing in mining operations Recycling:Impact crushers are crucial in recycling operations, where they are used to Impact crusher application and spare parts introduction

Mobile Impact Crushers RUBBLE MASTER

Mobile impact crushers are used to recycle concrete and asphalt and process natural rock They are easy to move on and between jobsites, which allows operators to crush on smaller jobsites Best of all they often come with an on 2024年2月20日 Impact crushers operate on a dynamic principle where the material to be crushed is fed into a chamber containing a highspeed rotor This rotor is equipped with a series of hammers or blow bars that spin at speeds What's the Difference: Impact Crusher vs Jaw They crush mediumhard to hard material The thyssenkrupp Polysius Impact Crusher produces a single stage perfect feed material for a vertical roller mill thyssenkrupp Polysius Impact Crushers are installed as stationary, semi Impact crusher thyssenkrupp Polysius Crushing Manufacturer of Impact Crushers Horizontal Shaft Impact Crusher, Vertical Shaft Impact Crusher offered by Arihant Industries, Vadodara, Gujarat Arihant Industries Manjalpur, Vadodara, Gujarat GST No24AACFA0037B2ZG Call Impact Crushers Horizontal Shaft Impact Crusher

.jpg)

HSI Or VSI Impact Rock Crusher: Which Is Best For Your Needs?

2023年8月21日 There are key differences between horizontal shaft impact (HSI) and vertical shaft impact (VSI) crushers, and understanding them will help you select the best impact rock crusher How Impact Rock Crushers Work Impact crushers use striking and highspeed impact forces to crush material Instead of compression or grinding, the particles are This kind of crusher can crush many kinds of materials with max feed size less than 500mm and crushing strength less than 360 MP It has the features of high ratio of crushing, high efficiency of crushing, easy to maintenance, etc In addition, impact crushers are more suitable to process granite, limestone, bank gravel etc in the area of Impact Crusher Liming Heavy IndustryHC Series Impact Crushers: HC Series Impact Crushers HC Series Impact Crushers are built on advanced technology with a combination of domestic applications The overall structure is simple, practical and reasonable Raw materials: Granite, limestone, concrete, lime, plaster Capacity: 501200t/hMax feeding size:300mm1600mm Application:Impact Crusher SanmeImpact Crushers Product description The impact crusher is a crushing machine that uses impact energy to crush materialsperiod; When the machine is workingcomma; driven by the motorcomma; the rotor rotates at a high speedperiod; When the material enters the blow bar action areacomma; it collides with the blow bar on the rotor and breakscomma; and then is Impact Crushers Impact Crushers and Mining Machinery

Mobile Impact Crushers, QI Mobile Impact Crusher SRP

Our mobile impact crushers are the result of combining the latest advancements in engineering technology and digitalization to provide a versatile and costeffective mobile crusher Everything that goes into the design of Sandvik Mobile Impact Crushers has the operator at the core, putting flexibility and productivity at the top of essential Our impact crushers are designed by skilled engineers and built in our complex machining shops, guaranteeing easy maintenance throughout the crusher’s use Reversible Impactors Williams Reversible Impactors are among the most advanced secondary or tertiary crushers On the market, offering high capacity size reduction of solids by midair Impact Crusher Machines Williams Patent CrusherWillpactors® are rugged, single rotor, primary impact crushers for high capacity, high reduction ratio, plus external product size adjustment These heavyduty impact crushers are engineered around four rotor sizes to provide capacities Willpactor® Primary Impact Crusher Williams 4 天之前 The impact rock crushers can crush materials smaller than 800 mm, such as granite, limestone, concrete, etc Its discharge size is adjustable Impact crushers are generally used as secondary crushers to reduce the Impact Crusher with Various Models Fote

.jpg)

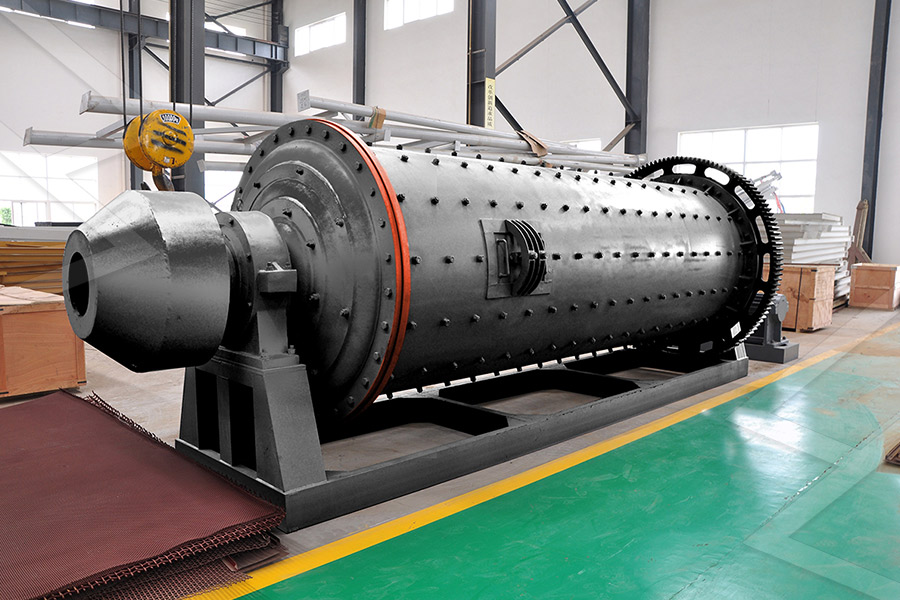

Understanding comminution: Compression

2020年8月18日 When compared to cones, impact crushers often have a lower capital cost, but can potentially incur high operating costs if the application has not been evaluated properly and has high abrasive qualities Our range of Impact Crushers create material reduction by providing a sudden impact force that causes the material to shatter along all the weakest fissures in the stone Controlling the flow of the material through the Impact Crusher requires features that vary from one style of Impact Crushers Primary McLanahanCrush Different To Dominate Serious Projects Efficiency and the lowest cost per ton is the aim of the game RUBBLE MASTER understands that when your machine is down, your crew is down, and you are bleeding money Impact Crushers RM J110X Mobile Jaw Crusher Scalping Screens Incline Screens Tracked Conveyors RecyclingRM 120X Mobile Impactor Crush Different RUBBLE MASTERThese crushers are suitable for a wide range of applications including the production of high quality manufactured sand, well formed aggregates and industrial minerals Crushers can also be used for shaping or removal of soft stone from aggregate WHY MEKA VERTICAL SHAFT IMPACT CRUSHER G MODEL? • Rock on rock design decreases operation costsVertical Shaft Impact Crushers – G Model– MEKA

.jpg)

Impact Crusher vs Jaw Crusher: Which One is Better for Your

Impact crushers work similarly but use an agitating arm instead of a rotating jaw This arm slams against the material repeatedly, breaking it into smaller pieces The main difference between these two types of machines is how efficiently they break down materials Jaw crushers are better at smallsize rocks and grits, while impact crushers are 2023年2月21日 There are several types of impact crushers available, including horizontal shaft impact crushers and vertical shaft impact crushers Each type operates on a different principle, but the basic working principle is the same Horizontal shaft impact crushers have a horizontal axis of rotation and use a blow bar that is fixed on the rotorThe Ultimate Guide to Impact Crusher Blow Bars AGICOUnlike other crushing machines like jaw crushers or cone crushers, which apply pressure to break the material, an impact crusher uses rapid collisions between the hammer and the target material Impact crushers are designed with heavyduty rotors that rotate at high speeds, allowing them to deliver tremendous force when striking the materialImpact Crusher working principle parts and maintenance2023年8月2日 Horizontal Shaft Impact Crushers Horizontal Shaft Impact Crushers, such as the New Holland, Andreas and MaxCap (which is a hybrid of the two) styles, are typically used for the primary size reduction of soft to medium hard materials These types of impact crushers can handle slightly abrasive, dry or wet material that is not stickyTypes of Crushers: What You Need to Know HUATAO GROUP

.jpg)

Impact Crushers Stedman Machine Company

What is an Impact Crusher? An impact crusher is a machine that uses striking as opposed to pressure to reduce the size of a material Impact crushers are designated as a primary, secondary, tertiary or quarternary rotor crusher The beauty of impact crushers is their versatility in terms of input material and output size There are many different designs out there but generally speaking impact crushers can produce material from 3" down The smaller the input How does an Impact Crusher work? RUBBLE 2024年7月17日 Choose gyratory or cone crushers for largescale production lines, and jaw or impact crushers for medium to smallscale operations 5 Investment and operating costs Initial investment: Gyratory and cone crushers have higher initial costs but lower longterm operating costs Jaw crushers and impact crushers are more costeffective initiallyTypes of Crushers: Choosing the Right One for Each Stage2024年8月14日 The Industries Impact Crushers Serve Aggregate Productions Impact crushers are commonly used in the production of aggregate materials for construction projects They can effectively crush various types of rocks to produce aggregates of different sizes and shapes Mining Operations Impact crushers are used to reduce the size of ore particles Impact Rock Crushers: A Comprehensive Overview

What is an Impact Crusher? Zenith Crusher

2024年10月18日 Impact Crushers are available in stationary, track, and portable configurations meeting any demand for any of these industries Although Impact Crushers generally have a higher operating cost than other crushers, they tend to produce a more uniform particle shape (cubical) which is desirable and produce more fines for hot asphalt producers2024年4月19日 Secondary crushers crush materials in the size range of 50 mm to 300 mm, which is determined by the type and size of the crusher They produce output sizes from 6mm to 100mm Secondary crushers can be divided into three main types: cone crushers, roller crushers, and impact crushersTypes of Crushers Explained: Everything You Need to KnowNordberg® NP Series™ HSI crushers consist of heavy rotor, wear resistant materials, and an optimal crushing chamber design This combination has proven revolutionary in improving capacity and product quality, as well as in reducing operating and wear costs Nordberg® NP™ crushers have a unique blow bar attachment systemNordberg® NP Series™ impact crushers MetsoCrushers Barry A Wills, James A Finch FRSC, FCIM, PEng, in Wills' Mineral Processing Technology (Eighth Edition), 2016 65 Impact Crushers Impact crushers (eg, hammer mills and impact mills) employ sharp blows applied at high speed to freefalling rocks where comminution is by impact rather than compression The moving parts are “beaters,” which transfer some of Impact Crusher an overview ScienceDirect Topics

.jpg)

Understanding the Impact Crusher Working Principle for

2023年2月23日 What is an Impact Crusher? Impact crushers, also known as impactors or horizontal shaft impact crushers, are crushing machines that use the principle of impact crushing to crush materialsThey are commonly used in mining, construction, and recycling industries to produce highquality cubical aggregates from various materials, including hard rock, soft rock, 2024年3月4日 Mining Operations:In mining applications, impact crushers are employed to crush hard and abrasive materials such as ore and minerals Their robust construction and high capacity make them suitable for primary and secondary crushing in mining operations Recycling:Impact crushers are crucial in recycling operations, where they are used to Impact crusher application and spare parts introduction