Cement Production Equment List

.jpg)

The Cement Plant Operations Handbook International

2019年4月30日 The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide Providing a comprehensive guide to the entire cement production process from raw materialCement manufacturing: components of a cement plant This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etcCement manufacturing components of a 5 天之前 The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks How Cement is Made Cement Manufacturing Process2024年5月22日 The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: A practical guide to improving cement manufacturing

.jpg)

Cement Production Process Cement

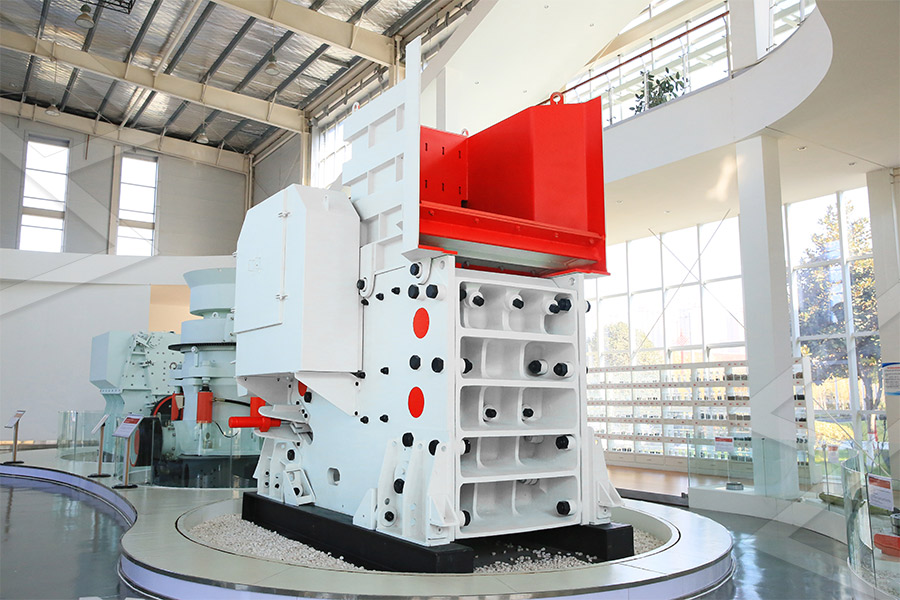

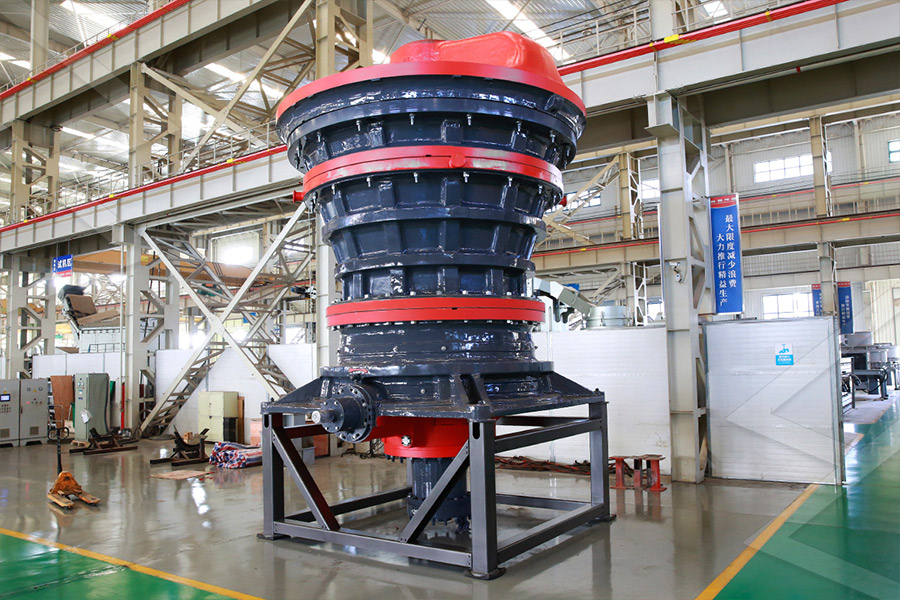

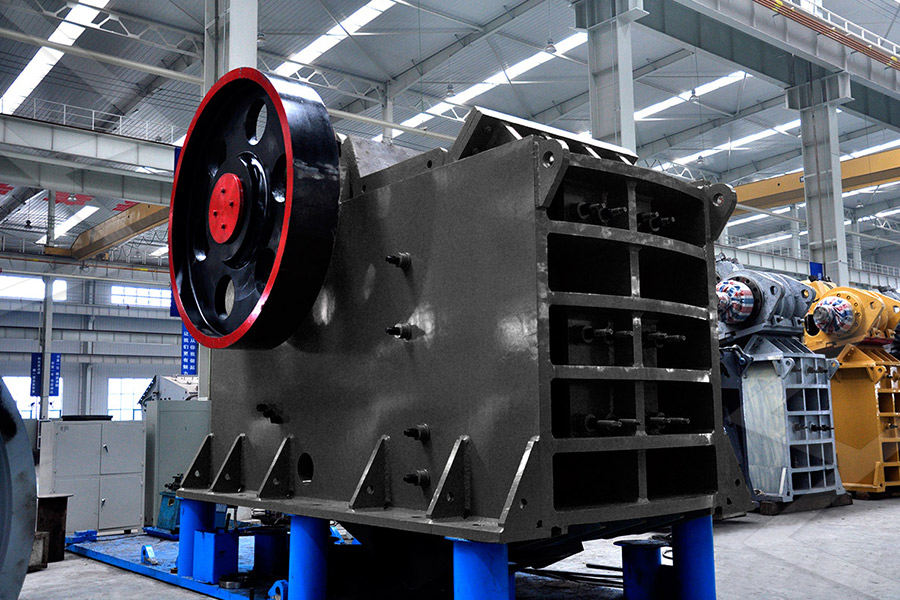

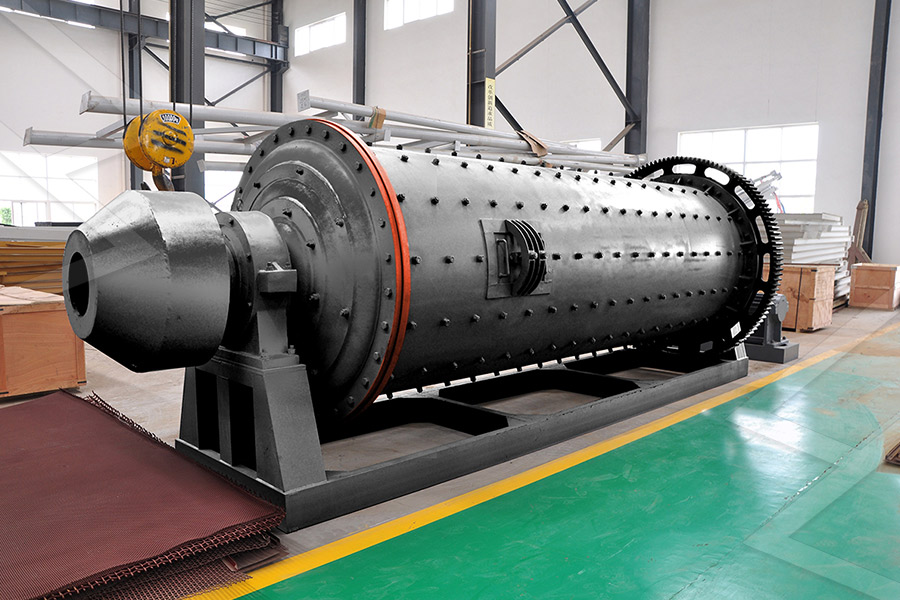

2020年8月25日 In general, a full cement production process includes the stone crushing, raw mill process, clinker process, and cement grinding process, cement packing process, and related processFully revised and updated with improved content, the new Sixth Edition of the Cement Plant Operations Handbook is now available Covering some 300 pages, the cement industry’s favourite technical reference book offers indepth The Cement Plant Operations Handbook 6th 2019年10月23日 %PDF14 %âãÏÓ 4 0 obj > endobj xref 4 173 00000 n 00000 n 00000 n 00000 n 00000 n Cement Plant: The Manufacturing Process On the one hand, basic indexes were used to adjust the hierarchy of renewable rate and nonrenewable ratio On the other hand, higher level indicators were designed to evaluate theMain equipment for the cement production process

.jpg)

Chapter 4 Cement Manufacturing and Process Control

2019年8月26日 Cement Manufacturing and Process Control 41 Cement Manufacturing: Basic Process and Operation To design the Refractory for the lining of different equipments in a Cement rotary kiln plays an important role in the cement production line AGICO supplies rotary kilns for dry process clinker calcination Vertical Shaft Kiln The vertical shaft kiln is a type of traditional cement clinker calcination equipment, Cement Manufacturing Equipment for Sale2023年10月13日 Cement producers and their investors are navigating evolving risks and opportunities as the sector’s climate and sustainability implications become more prominent While many companies now Global database of cement production assets and upstream Delivering truly sustainable cement production requires a fully integrated approach that spans your entire plant With our marketleading MULTICOR cement processing solutions, we help you meet the defining challenges in Cement processing equipment Qlar

.jpg)

Cement IEA International Energy Agency

2024年10月19日 Cement production declined significantly in 2022, down 5% to 4 158 Mt But this number hides contrasting regional trends Despite the decrease in production in China (105% yearonyear), as a result of the country's real estate crisis and policies to respond to the coronavirus pandemic, China remains the leading global cement producer Sustainable cement production; Alternative fuels in cement kilns; Cement kiln safety; Energy efficiency in cement kilns; Future of cement kilns TO Download this post and all the books and excel sheets and my personal notes and presentations I collected about cement industry in the last 30 years click the below paypal linkComprehensive Guide to Cement Kilns: Processes, Types, 5 天之前 Stage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing Process3 天之前 They offer a range of equipment and production lines for the manufacturing of various concrete products and elements With a focus on lightweight wall panels, precast concrete elements, and cement equipment, they provide efficient and durable solutions to their customers 7 BHAI Pumpcrete (P) Ltd Website: bhaicoTop 28 Players in Cement Equipment Production Inven

.jpg)

How Cement is Made Portland Cement Association

Each step of the cement production process is carefully monitored to ensure efficiency and quality Grinding, Mixing, and Blending The rock fragments are finely ground and combined with other ingredients including clay, chalk, marl, shale, slate, sand, and iron ore Recycled industrial byproducts used to supplement some or all of these Clinker production is the most energyintensive stage in cement production, accounting for over 90% of total industry energy use Clinker is produced by pyroprocessing in kilns These kiln systems evaporate the free water in the meal in preheater cyclone, calcite the carbonate constituents (calcination) in calciner, and form Portland cement Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT2024年9月26日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by excavators Cement Extraction, Processing, Manufacturing Britannica2024年10月14日 The research covers teh entire value chain, from quarrying to cement manufacturing and equipment CW Research’s unique and longproven knowledge of gray cement, clinker, white cement, aluminous cement, fiber cement and oilwell cement makes the company the most reliable option in the research marketWorld Cement Equipment Market and Forecast Report 2022

.jpg)

Cement Plant, Cement Equipment Cement

Cement plant is necessary for cement production, and mainly consists of a series of cement equipment apply for the preparation of cement raw materials, clinker production, and finished cement production, such as a cement mill, cement The new dry process of cement manufacturing is the latest and most efficient modern cement production technology It takes suspension preheating and predecomposition outside the kiln as the core technology, and widely applies the Cement Plant EPC Service Equipment Supply2024年6月1日 Cement production is a complex and essential process that involves several stages and impacts various aspects of the construction industry and the environment The first step in cement production is the extraction of raw materials, primarily limestone, clay and shale [34] These materials are typically obtained from quarries or mines, where Decarbonising cement and concrete production: Strategies, 2024年5月22日 Figure 2: PGNAA and PFTNA capabilities in cement production For cement manufacturers, neutron activation analysis is a particularly compelling technique because of its ability to: • Directly measure key compounds of interest, including Ca, Si, Al, and Fe oxides as well as other important elements such as MgO, Na 2Costefficient strategies for sustainable cement production

.jpg)

Modernizing cement manufacturing in China leads to

2022年11月17日 NSP rotary kilns started to account for more than 10% of the market share in 2001, and China’s national cement production peaked in 2014 Therefore, 2001 and 2014 are selected as typical years 2024年3月1日 So, we’ve put together a list of our blog articles related to the cement production process and analysis Here are the top 15 of our most read cement articles, in no particular order: Extending Quarry Life through Raw Material Analysis in Cement Production While the life of a cement plant quarry is by its very nature finite, it can be Everything about Cement Production Thermo Fisher Scientific2019年10月23日 %PDF14 %âãÏÓ 4 0 obj > endobj xref 4 173 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n 00000 n Cement Plant: The Manufacturing Process2024年1月8日 Figure 1 Breakdown of Emission Sources from Concrete Production Concrete is the world’s mostused human made material Step 1 Quarrying, Grinding, and Pretreating Step 2 Clinker Production Step 3 Cement Production Step 4 Concrete Production The production process can be simplified to four major steps These include: quarrying, grinding, andCement and Concrete 101 Industrial Innovation Initiative

Assessment on Cement Production Practice and

2020年1月1日 The combination effect of supplementary cementitious materials in the production of highstrength concrete production is an effective way to reduce the amount of cement required while contributing Find the most uptodate statistics and facts about the US cement industry Switzerlandbased cement producer Holcim topped the list of leading cement manufacturers worldwideUnited States cement industry statistics facts Statista2023年9月11日 Cement Grinding Plant The cement grinding plant mainly used in crushing and preheating of raw materials, and grinding and packaging of cement And it is mainly applied to deal with in Φ4×60m Rotary Kiln Main Technical Performance of 460m Rotary Kiln: 1 Production capacity: 2500t/d new type dry process cement production line 2Cement Production Line,Cement Machine,Rotary Kiln 2015年12月1日 Comminution and especially cement grinding still account for the majority of the electrical energy demand of cement production As Fig 12 shows, between 60% and depending on cement properties up to 70% of the roughly 100–110 kWh of electrical energy per ton of cement are used for comminution processes [5], [45] It has to be noted that these Process technology for efficient and sustainable cement production

Environmental impact of cement production and Solutions:

2022年1月1日 As the demand for cement supply is continually growing, this causes an increase in the use of aggregate, especially limestone since it is important in the production of Portland cement [13], [14]Exhaustion of the earth’s nonrenewable resources is a growing dilemma when the reason is that the energy consumption has rapidly increased during the 21st century [15]2018年8月17日 The evolution of the Ethiopian cement industry can be delineated into three noteworthy phases: the commencement of cement production and modernization until 1984, a surge in construction (PDF) The Cement Industry in Ethiopia ResearchGate1 Introduction and composition of Portland cement 2 Raw materials 3 Production of cement clinker 4 Characterisation of Portland cement clinker 5 Grinding fineness of cement 6 Tests of cement quality 7 The hydration of Portland cement 8 The nature of hardened cement paste 9 Portland cements and related blended cements 10 Admixtures and MOST IMPORTANT BOOKS IN CEMENT INDUSTRY2024年5月22日 Premium Statistic Cement production capacity of selected top companies 2024 Premium Statistic Revenue of China National Building Material 20122022Global cement industry statistics facts Statista

Cement Production an overview ScienceDirect Topics

343 Cement production Cement production is one of the largest CO 2emitting industries globally, with the US contributing 643 MMT of CO 2 in 2014 [38] In 2014, the US produced 826 MMT of cement while the world produced a total of 4180 MMT China accounts for the majority of production, claiming 596% of global cement productionMEKA has added a new concrete batching plant in Jordan to its hundreds of concrete batching plant references in the Middle East MEKA engineers have successfully installed the C 100 Compact Concrete Batching Plant for our customer AlMoasron, one of the leading companies in the cement industry in Jordan, and concrete production started READ MOREConcrete Batching Plants MEKA GlobalCement rotary kiln plays an important role in the cement production line AGICO supplies rotary kilns for dry process clinker calcination Vertical Shaft Kiln The vertical shaft kiln is a type of traditional cement clinker calcination equipment, Cement Manufacturing Equipment for Sale2023年10月13日 Cement producers and their investors are navigating evolving risks and opportunities as the sector’s climate and sustainability implications become more prominent While many companies now Global database of cement production assets and upstream

Cement processing equipment Qlar

Delivering truly sustainable cement production requires a fully integrated approach that spans your entire plant With our marketleading MULTICOR cement processing solutions, we help you meet the defining challenges in 2024年10月19日 Cement production declined significantly in 2022, down 5% to 4 158 Mt But this number hides contrasting regional trends Despite the decrease in production in China (105% yearonyear), as a result of the country's real estate crisis and policies to respond to the coronavirus pandemic, China remains the leading global cement producer Cement IEA International Energy AgencySustainable cement production; Alternative fuels in cement kilns; Cement kiln safety; Energy efficiency in cement kilns; Future of cement kilns TO Download this post and all the books and excel sheets and my personal notes and presentations I collected about cement industry in the last 30 years click the below paypal linkComprehensive Guide to Cement Kilns: Processes, Types, 5 天之前 Stage of Cement Manufacture There are six main stages of the cement manufacturing process Stage 1: Raw Material Extraction/Quarry The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), shale, fly ash, mill scale, and bauxite The ore rocks are quarried and crushed into smaller pieces of about 6 inchesHow Cement is Made Cement Manufacturing Process

Top 28 Players in Cement Equipment Production Inven

3 天之前 They offer a range of equipment and production lines for the manufacturing of various concrete products and elements With a focus on lightweight wall panels, precast concrete elements, and cement equipment, they provide efficient and durable solutions to their customers 7 BHAI Pumpcrete (P) Ltd Website: bhaicoEach step of the cement production process is carefully monitored to ensure efficiency and quality Grinding, Mixing, and Blending The rock fragments are finely ground and combined with other ingredients including clay, chalk, marl, shale, slate, sand, and iron ore Recycled industrial byproducts used to supplement some or all of these How Cement is Made Portland Cement AssociationClinker production is the most energyintensive stage in cement production, accounting for over 90% of total industry energy use Clinker is produced by pyroprocessing in kilns These kiln systems evaporate the free water in the meal in preheater cyclone, calcite the carbonate constituents (calcination) in calciner, and form Portland cement Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT2024年9月26日 Cement Extraction, Processing, Manufacturing: Raw materials employed in the manufacture of cement are extracted by quarrying in the case of hard rocks such as limestones, slates, and some shales, with the aid of blasting when necessary Some deposits are mined by underground methods Softer rocks such as chalk and clay can be dug directly by excavators Cement Extraction, Processing, Manufacturing Britannica