Ban Of Stone Crushing In Faridabad Vibration Screen For Screening Of The Product

.jpg)

Shortcomings of Vibrating Screen and Corrective Measures:

2019年7月27日 The work consists of development of a DEM model for the various vibrating mode of the screening such as linear and circular vibration of the screen It was found that the 2024年9月17日 In the screening process, the movement of the particles on the screen is mainly affected by the vibration of the screen plate, causing the relative movement of the particles on Research on Vibrating Screen Screening Technology and 2009年7月1日 The ideal motion characteristics for the vibrating screen was presented according to the principle of screening process with constant bed thickness A new vibrating screen with Dynamics and screening characteristics of a vibrating screen 2013年1月1日 The vibration mode of the vibrating screen can be divided into three types: linear vibration, circular vibration and elliptical vibration Particles on the screen deck exhibit different Influence of vibration mode on the screening process

.jpg)

Comparative study on the screening performance of a vibrating screen

2024年2月1日 In this study, we developed a novel screening device that combines screening and kneading This device offers several advantages over traditional screening vibration 2023年2月23日 Vibration screening using trenches (open or infill) can be quick, simple, easily adoptable, and costeffective way to implement nearby or far away from the vibration sources A stateoftheart review paper on the vibration screening 2021年9月22日 In this paper, the dewatering and screening process of vibratingdewatering screen is studied by the combination of simulation test and physical experiment The simulation model of dewatering screening process is Study on screening performance and parameter 2020年6月24日 investigates the vibration characteristics of sand and screen units in an artificial sand production plant whose operation is multiple with several actuators different exciting Vibration Diagnosis of Sand Units in a Stone Crusher

Ban Of Stone Crushing In Faridabad Vibration Screen For Screening

Crusherstone crushing units faridabad stone crushing units faridabad h the stone crushing units will furnish on Hand Arm Vibration, Grip Strength Assessment and the 2017年6月25日 Where 2021年11月1日 The variable elliptical vibrating screen (VEVS) adopted the simple biaxial unbalanced excitation system, which helps to realize the equalthickness screening by Variable elliptical vibrating screen: Particles kinematics and 2023年9月1日 For example, a highfrequency screen may be necessary for fine screening applications, while a trommel screen may be more suitable for screening larger materials Screen size and capacity: The size of the screen and its capacity will depend on the volume of material being processed and the desired throughput rateHow To Size and Select a Vibrating Screen for an Aggregate 2020年6月24日 screen units [12‐13] Recently, in order to improve the screening efficiency of the vibration screen and make the vibration process smoother, a new type MR damper was proposed and evaluated at a laboratory level [14] Furthermore, shape memory alloy (SMA) is applied to Vibration Diagnosis of Sand Units in a Stone Crusher

.jpg)

Shortcomings of Vibrating Screen and Corrective Measures:

2019年7月27日 The screening process is usually carried out for separating two or more materials of different shapes, particle sizes and densities []The vibrating screen has wide range of application in minerals industries for the screening of minerals, mineral ores and ore slurries []It also has applications in mining industries especially in coal mining industries []Ore Tech Industries Private Limited village Jajru Industrieal Area Plot No 1a Ballabgarh Jajru Ballabhgarh, Faridabad , Haryana, IndiaOre Tech Industries Private Limited, Faridabad2022年5月14日 Simulation was performed before implementation to verify and adjust the algorithm In order to test the algorithm on the crushing stage, a separate control box was developed based on a Crusher Controller Unit (CCU) Several case studies have also been conducted by different researchers which showcase the realworld scenario of stone crushing Stone Crushers: A Technical Review on Significant Part of2023年3月6日 As experience shows, when one determines the energypower parameters of crushing and grinding processes by using the existing methods, the power of motors used in drives of existing crushers of various types often turns out to be excessive [10, 11]In this case, the drive will operate at a relatively low load (ratio of the power consumed by the working body Study of the EnergyPower Parameters of the Crushing

.jpg)

Study on screening performance and parameter optimization

2021年9月22日 In improving dewatering performance, Dong et al 1,2 developed a vibratingdewatering screen with a unique structure that uses side plate beam excitation Shi 3 studied the highfrequency coal slime vibratingdewatering screen, and analyzed the parameters selection method and structural design characteristics of the machine In optimizing structural strength, 2021年10月1日 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters A simplified threedimensional model of the vibrating screen, shown in Fig 1, is established to reduce the complexity but realize the actual screening effectAdditionally, the sieving process in the simulation experiment is Stepwise shape optimization of the surface of a vibrating screenTo clarify your payment options for purchasing Inclined Vibration Screen, please note that the available payment methods depend on the POOJAENTERPRISES preference As the Inclined Vibration Screen belongs entirely to the POOJAENTERPRISES, they can choose the mode of payment that suits them best Currently, the available methods our sellers support are Cash, Inclined Vibration Screen in Faridabad POOJAENTERPRISES2022年5月1日 This content was downloaded from IP address 16243237108 on 24/11/2022 at 09:41Design of Vibrating Screen Separation Equipment for

.jpg)

How To Size and Select a Vibrating Screen for

2022年2月15日 How to select the right aggregate screen Because screening plays such an important role in producing the required specifications of a final product, it is imperative that the right screen is selected for the job Vibrating 2009年7月1日 The screening effect is strengthened by a proper, , which makes fine grained material laminate and penetrate the mesh with a thinner material bed: this improves the actual service efficiency of the screen surface Table 1 Vibration parameters of five points on screen surface Position of points 1 2 046 056 531 331 1109 3 041 044 452 282 Dynamics and screening characteristics of a vibrating screen 2024年5月30日 The proper selection, installation, commissioning, and operation of vibrating screen is essential for ensuring the overall productivity, product quality, and costeffectiveness of a stone crushing operation Proper Installation Ensure the screen is mounted on a sturdy, level foundation to prevent excessive vibrations and maintain alignmentEffective Installation, Commissioning, and Operation of Vibrating Screen2022年12月28日 Screening refers to the process of breaking up the material into different size pairs through one or several layers of screen surface In the screening process, the sieved raw material continuously into the screening machinery, then, less than the size of the screen hole material will be through the screen hole, this part of the material is the product of the screen; Mineral Screening: The Complete Guide Miningpedia

A review on the advanced design techniques and methods of vibrating

2019年4月1日 For the clean and efficient utilization of coal, coal preparation is an important measure to solve the problem of air pollutant emissions, solid waste generation and save coal resources in the world [1, 2]Screening is the basic process for cleaning and efficient utilization of coal, and is mainly realized via vibrating screen [3]A conventional largescale coal preparation 2024年4月1日 A DoE was applied to the crushing plant with a full factorial design containing 2 factors and a 3level approach, where variables CSS and ES are varied over their operational range, resulting in 9 experiments, see Table 1The range corresponds to CSS = 16, 20 and 24 mm and nominal ES +/ 8 % The eccentric speed was controlled using a variable frequency Application of design of experiments (DoE) in evaluating crushing 2013年1月1日 The motion of a vibrating screen can be defined as three types, linear, circular or elliptical, depending upon the trajectory Fig 1 shows that λ is the amplitude and β is the vibration direction angle of the model The simulations use an improved DEM dry contact softsphere model [13], [14] Fig 2 shows that k n and d n are the normal stiffness and normal damping; k Influence of vibration mode on the screening process2023年7月1日 The discrete element method (DEM) is able to simulate the particleparticle and particlescreen surface collisions It is easier to realize the regulation of the motion form of the screen machine, which is now widely used in the optimization study of vibrating screening process (Elskamp KruggelEmden, 2015; Elskamp, KruggelEmden, Hennig, Teipel, 2015)Collaborative optimization of linear vibrating screen screening

Kinetic model of vibration screening for granular materials

2024年5月1日 Screening is a common technique for materials separation according to the physical sizes To achieve different objectives, many screening devices and operation modes have been proposed (Makinde et al, 2015; Shen et al, 2021; Yu et al, 2022)Applying vibration to the screen is an effective way to improve operation performance, which has greatly The FlipFlow Screen is extensively utilized in the vibrating screening process for the treatment of particle matter In this study, a fourdegreeoffreedom (4DOF) FlipFlow Screen was proposed The granules in the 4DOF FlipFlow Screen were modeled using the discrete element method The screening process of the 4DOF FlipFlow Screen was simulated by multiflexible body The MFBDDEM coupling simulation approach for the2015年7月26日 Screen Vibration Patterns Very close screening is not required and some sort of moving bar or ring grizzly can well be used, but the modern method is to employ for the purpose a heavyduty vibrating screen of Vibrating Screen Working Principlestone mining and crushing area of Middle catchment of Dwarka river basin of Eastern India Fieldbased noise recording has been done at di erent times in every recordedNoise vulnerability of stone mining and crushing in

Modeling and parameter optimization for the design of

2015年11月1日 Chen and Tong, 2009, Chen and Tong, 2010 performed DEM modeling of linear vibration screen to analyze the relationship between screening efficiency and vibration parameters Besides, the screening process of banana screens was simulated using DEM by Dong et al (2009) and Cleary et al, 2009a, Cleary et al, 2009b2018年12月4日 Geometric comparison of dynamic modeling and DEM, showing the change in the center of mass due to the load, with (1) upper screen deck, (2) rigidbody model, (3) lower screen deck, and (4) feed chute(PDF) Dynamic Modeling of a Vibrating Screen Considering 2023年2月23日 A stateofthe art review of research is conducted on the vibration screening using different trench barriers Factors that affect the performance of the trench, design of the trench, and further scope of developments in the field of ground vibration attenuation are major emphasized part of this study Over six decades, numerous researches have been conducted A stateoftheart review paper on the vibration screening 2017年5月30日 different stages of the crushing process and in final product separation Designed as a nonwelded frame with adjustable vibration features for different material types and screening sizes, Meka screens provide screening efficiency that is high quality and dependable Our screens come in various sizes starting from 2 m² up to 16 m²CRUSHING SCREENING Crushing and Screening

.jpg)

Basic concepts of vibrating screens: What they are, what they

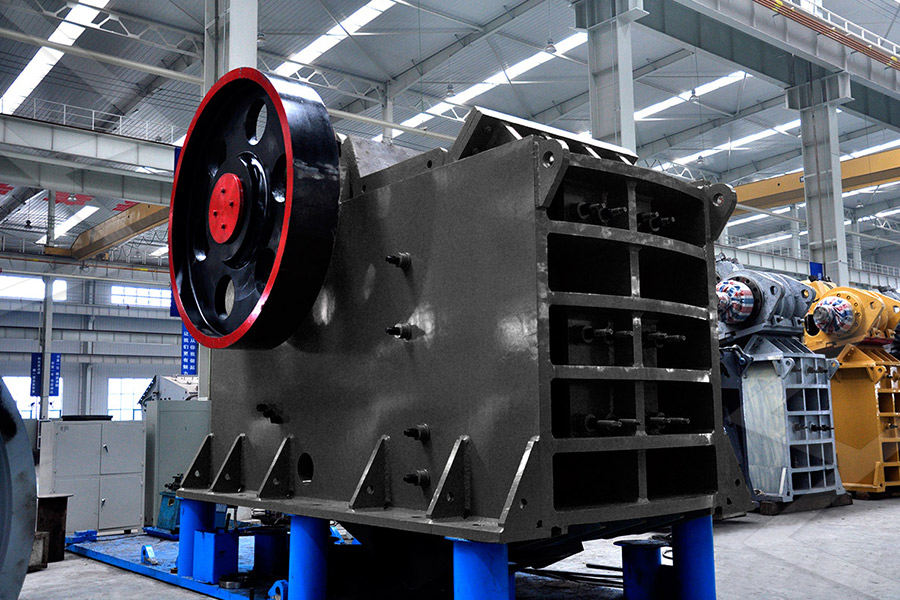

For the correct advancement of the product it is necessary that the process is continuous, and it is due to the vibration if the screening surface is horizontal Most of the screens have a certain inclination in such a way that the advance movement of the product is due to a combination between gravity and vibration Screening elements2020年6月30日 to improve the screening e ciency of the vibration screen and make the vibration process smoother, a new type MR damper was proposed and evaluated at a laboratory level [14] Furthermore, shape Stone crushing plays a key role in the reduction of particle size of rocks or stones [8–21] The jaw crusher is defined asVibration Diagnosis of Sand Units in a Stone Crusher 2021年12月3日 The present study investigates the effects of rock crushing circuits on aggregate quality For this purpose, a crushingscreening plant located in Vize (Kırklareli, Turkey) was considered(PDF) INVESTIGATION OF ROCK AGGREGATE QUALITYTherefore, the capital cost for the process is lowered while maintaining a high quality of the asphalt mixture Moreover, high frequency screen applies intensive vibration directly onto the screen media, such high RPM allows asphalt pavement material to achieve a higher stratification and separate at a faster rate[3] Mineral processing [edit]What Is A Vibrating Screen? HUATAO GROUP

.jpg)

How To Size and Select a Vibrating Screen for an Aggregate

2023年9月1日 For example, a highfrequency screen may be necessary for fine screening applications, while a trommel screen may be more suitable for screening larger materials Screen size and capacity: The size of the screen and its capacity will depend on the volume of material being processed and the desired throughput rate2020年6月24日 screen units [12‐13] Recently, in order to improve the screening efficiency of the vibration screen and make the vibration process smoother, a new type MR damper was proposed and evaluated at a laboratory level [14] Furthermore, shape memory alloy (SMA) is applied to Vibration Diagnosis of Sand Units in a Stone Crusher 2019年7月27日 The screening process is usually carried out for separating two or more materials of different shapes, particle sizes and densities []The vibrating screen has wide range of application in minerals industries for the screening of minerals, mineral ores and ore slurries []It also has applications in mining industries especially in coal mining industries []Shortcomings of Vibrating Screen and Corrective Measures: Ore Tech Industries Private Limited village Jajru Industrieal Area Plot No 1a Ballabgarh Jajru Ballabhgarh, Faridabad , Haryana, IndiaOre Tech Industries Private Limited, Faridabad

.jpg)

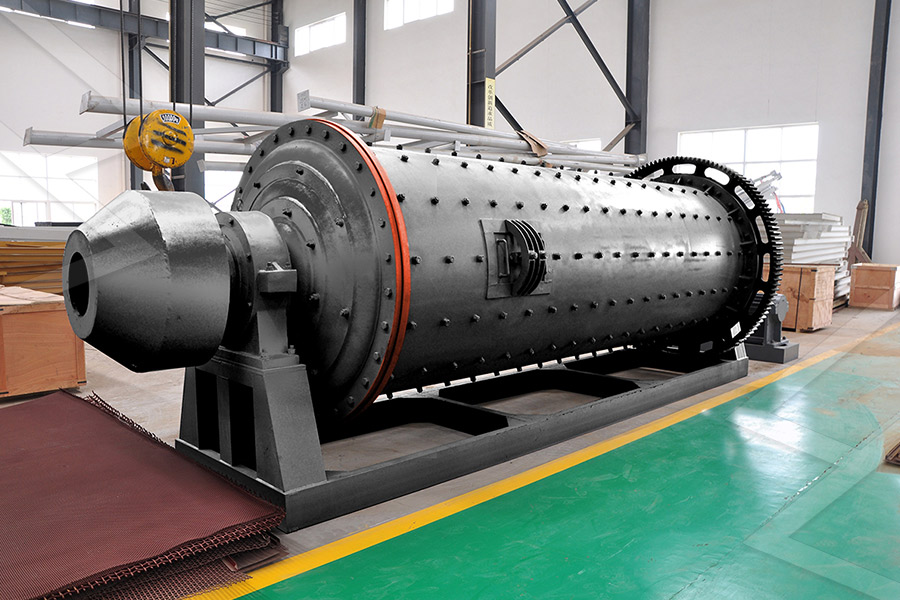

Stone Crushers: A Technical Review on Significant Part of

2022年5月14日 Simulation was performed before implementation to verify and adjust the algorithm In order to test the algorithm on the crushing stage, a separate control box was developed based on a Crusher Controller Unit (CCU) Several case studies have also been conducted by different researchers which showcase the realworld scenario of stone crushing 2023年3月6日 As experience shows, when one determines the energypower parameters of crushing and grinding processes by using the existing methods, the power of motors used in drives of existing crushers of various types often turns out to be excessive [10, 11]In this case, the drive will operate at a relatively low load (ratio of the power consumed by the working body Study of the EnergyPower Parameters of the Crushing 2021年9月22日 In improving dewatering performance, Dong et al 1,2 developed a vibratingdewatering screen with a unique structure that uses side plate beam excitation Shi 3 studied the highfrequency coal slime vibratingdewatering screen, and analyzed the parameters selection method and structural design characteristics of the machine In optimizing structural strength, Study on screening performance and parameter optimization 2021年10月1日 The structure of a real vibrating screen is particularly complicated and mainly comprises a screen box, screen mesh, and vibration exciters A simplified threedimensional model of the vibrating screen, shown in Fig 1, is established to reduce the complexity but realize the actual screening effectAdditionally, the sieving process in the simulation experiment is Stepwise shape optimization of the surface of a vibrating screen

Inclined Vibration Screen in Faridabad POOJAENTERPRISES

To clarify your payment options for purchasing Inclined Vibration Screen, please note that the available payment methods depend on the POOJAENTERPRISES preference As the Inclined Vibration Screen belongs entirely to the POOJAENTERPRISES, they can choose the mode of payment that suits them best Currently, the available methods our sellers support are Cash, 2022年5月1日 This content was downloaded from IP address 16243237108 on 24/11/2022 at 09:41Design of Vibrating Screen Separation Equipment for